A Practical Guide to AI Applications in Digital Warehouse Management

A new study says more than 60% of warehouses have old systems and manual work as their main problem for being efficient. AI applications in digital warehouse management use smart algorithms to do tasks automatically, look at lots of data, and help people make better choices. Warehouses often face these problems:

Trouble with data because of paper records

People do not want to use new technology

Worries about cybersecurity and being stuck with one vendor

Not enough skilled workers

Worries about ethics and growing the system

AI helps fix these problems by making work faster, more correct, and safer.

Key Takeaways

AI applications do jobs in warehouses by themselves. This cuts down on mistakes and makes things faster. Orders get filled quicker and work gets done better.

AI systems give real-time data to managers. This helps them make fast choices. Teams can fix problems right away and plan well.

Smart order picking systems help workers pick the right items. This means fewer mistakes and faster work. It also lowers returns and makes customers happier.

Predictive maintenance with AI helps machines last longer. It stops machines from breaking down often. This saves money on repairs and keeps things running smoothly.

Training workers to use AI tools is very important. Practice lessons help workers learn and feel sure about using new technology.

AI Applications Transforming Warehouse Management

AI applications are changing how warehouses work. These tools help companies fix problems faster and with fewer mistakes. Warehouses need smart solutions because they have more orders and products now. Fast-moving businesses like e-commerce, retail, and logistics use technology to keep up with customers.

Automation and Robotics

Robots and machines do many jobs people did before. These machines pick, pack, and move things in the warehouse. Cube storage robots, robotic arms, drones, and self-driving forklifts work together to make work easier.

Robots help companies fill orders quickly and make fewer mistakes. In e-commerce and retail, robots help finish orders faster when lots of people buy things. Third-party logistics companies use machines to help many clients and grow fast. In the pharmaceutical industry, machines keep track of items and follow strict rules. Food and drink warehouses use robots to handle items that need cold or special care. Automotive parts warehouses use robots to store things neatly and save space.

Robots and smart storage systems move items and manage orders without people.

Automation helps stop mistakes and saves time.

Inventory Optimization

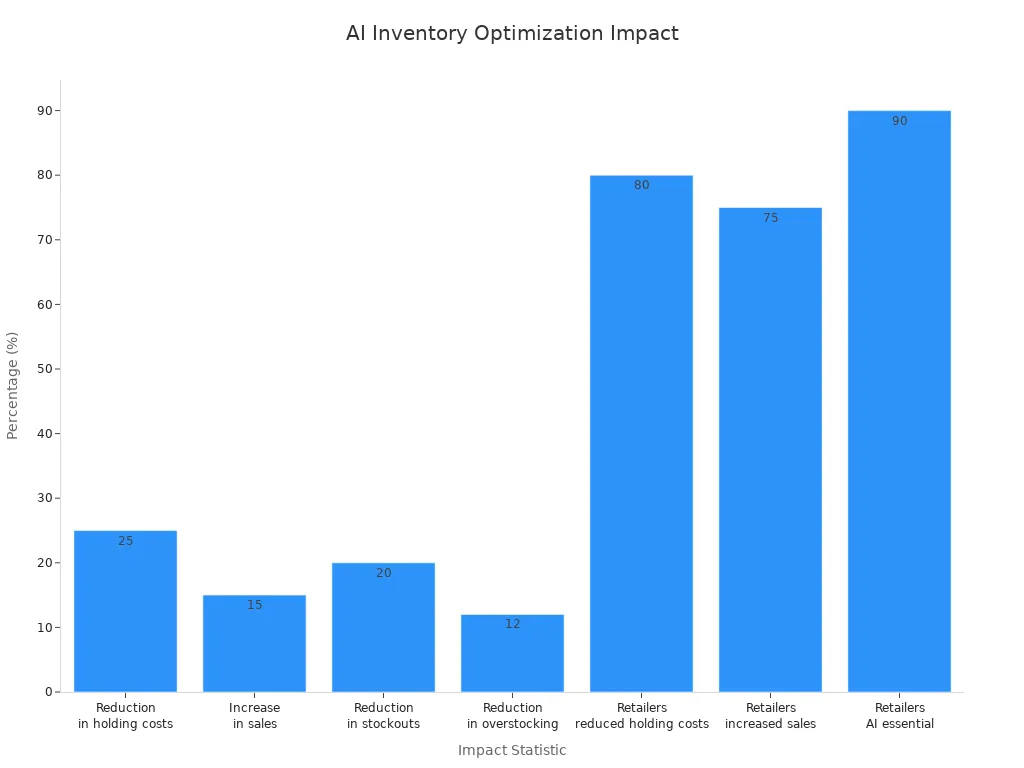

AI applications help companies keep the right amount of products. These systems use data to guess what will sell and when. Machine learning looks at old sales and market changes to predict what people will buy. This helps companies order only what they need and not have too much or too little.

Statistic | Impact |

|---|---|

Better cost savings | |

15% more sales because stock is available | More money earned |

20% fewer times products run out | Better stock control |

12% less extra stock | Less waste and lower costs |

80% of stores spent less on storing products | Many stores saved money |

75% of stores sold more | Good results for stores |

90% of stores say AI is needed to compete | AI is important for business |

Big companies like Walmart use AI to manage products, which saves money and makes work better. A large store chain used AI to set product levels and guess what people would buy. AI helped some companies avoid running out of products during busy holidays.

AI-powered inventory management helps companies waste less and avoid having too much by guessing what people will buy and setting the right product levels.

Real-Time Data and Visibility

AI applications give warehouse teams instant information. Real-time data helps managers see what is happening and make quick choices. These systems collect data from many places and show clear answers. Teams know what to do next, so they worry less and guess less.

Seeing data helps make better plans and saves money.

Teams get clear steps for what to do next.

AI applications make warehouse management smarter and easier. Companies use these tools to fix problems and stay ahead.

Enhancing Order Fulfillment and Demand Forecasting

Smart Order Picking

Smart order picking uses AI to help workers pick items fast and right. These systems show clear steps for new and old workers. Workers can start quickly without much training. Managers use real-time data to plan and give out tasks. This helps stop mistakes and makes work smoother. Automated systems gather products for orders with speed and care. Companies get fewer returns because picks are more correct and steady.

Workers pick items faster and make fewer mistakes.

Managers use real-time data to plan and give out jobs.

Automation helps make picks more correct and lowers returns.

Tip: Smart order picking lets companies fill more orders in less time, even when it is busy.

AI-Powered Demand Forecasting

AI-powered demand forecasting looks at old sales, market changes, and what customers do. These tools guess what products people will want and when. Warehouse managers use these guesses to order the right amount of stock. This keeps shelves full and gives customers what they need. Companies do not have too much or too little inventory. AI applications help businesses change plans fast when demand changes.

Benefit | Result |

|---|---|

Better guesses | Fewer times out of stock |

Right stock levels | Less waste |

Fast changes | Happier customers |

Improving Accuracy and Speed

AI applications help make warehouse work more correct and faster. Smart systems watch every step of the order process. Workers get clear steps, so they make fewer mistakes. Automation does boring jobs, which saves time. Real-time updates help managers see problems and fix them fast. Companies send orders faster and keep customers happy.

Note: Fast and correct order filling helps customers trust companies and helps them grow.

Predictive Maintenance and Operational Efficiency

Equipment Monitoring

Warehouse machines need regular checks to work well. AI equipment monitoring uses sensors to watch machines all the time. These smart systems find problems early and tell managers before things break. This helps teams plan repairs and stop sudden breakdowns.

AI predictive maintenance helps machines last about 40% longer.

Finding problems early saves 12-18% on energy.

Planned maintenance needs 3.2 times less work than emergency fixes.

Maintenance costs usually go down by 18-25%.

AI helps warehouses keep machines working longer and spend less on repairs.

Reducing Downtime

Downtime is when machines stop working. This slows down the warehouse. AI systems help teams fix problems before they get worse. Warehouses using AI for predictive maintenance have 30% less downtime. Less downtime means workers finish more orders and customers are happier. Managers can plan better because they know when machines need care.

Tip: Less downtime helps warehouses work faster and saves money.

Workflow Optimization

AI workflow optimization makes warehouse jobs easier. These systems use data to plan the best way to use workers and machines. They guess busy times and help managers put workers where they are needed most. AI helps manage inventory by guessing what will sell and planning the best picking routes. This makes order fulfillment faster. Smart space management puts products in the best spots, so teams use all the warehouse space. AI helps people and robots work together by giving each the right jobs. This helps everyone work better and lowers worker stress.

Faster picking and order filling

Smarter use of warehouse space

Improved teamwork between people and robots

AI makes warehouse work more efficient, correct, and saves money.

Overcoming Implementation Challenges

Data Integration

Many warehouses have trouble connecting AI to their old software. Some companies use old tools that do not match new AI. This can make it hard to keep things running well. AI needs good data to make smart choices. Warehouses have lots of data, but some is messy or not useful. Teams must organize data so AI can help them.

Challenge | Description |

|---|---|

It is hard to connect AI with old software. This can make work stop or slow down. | |

Data Management | AI needs good data to guess right. Managing lots of data is tough. |

Workforce Transition | Workers need to learn new skills and ways to work. |

Managers should think about these problems before starting with AI.

Workforce Training

Training workers is important for using AI in warehouses. Employees need to learn how AI helps them do their jobs. Companies should give hands-on lessons and show how AI fits in daily work. This helps workers feel ready for changes.

Give training that fits the job.

Use digital tools in daily work.

AI works with people, not instead of them.

Workers do less data entry and more data checking.

AI makes work easier and gives new job choices.

AI is changing warehouse jobs by making work less hard and creating new tech roles. This means training must change too.

Scalability

Scalability means AI can grow with the company. Big warehouses can buy better AI and grow fast. Small warehouses may pay more and know less, but they can still use AI as they get bigger. AI helps handle more data, customers, and orders without costing too much.

Warehouse Size | Scalability Benefits |

|---|---|

Large | Can buy better AI and grow fast. |

Small | Has problems but can use AI as it grows. This helps them stand out. |

Costs a lot at first

Not enough experts

Hard to connect with old systems

AI helps all companies grow and compete, no matter their size.

Actionable Steps for Adopting AI Applications

Assessing Readiness

Warehouse teams first check if they are ready for new technology. They look at their data and see if it is clean. Teams also check if their computers and software can use AI tools. Managers see if workers can learn new systems. This check helps find problems and plan for changes.

Tip: Clean and neat data helps AI work well. Teams should fix data issues before using AI.

Selecting Solutions

Picking the right AI tools means finding what fits best. Teams set goals and choose tools that solve big problems. They make sure new tools work with old systems. Managers look at things like demand forecasting, computer vision, and robotics. The table below shows what to think about:

Explanation | |

|---|---|

Align with operational needs | Solutions should fix warehouse challenges directly. |

Define clear goals | Clear objectives help measure success. |

Ensure system compatibility | New tools must work with current systems. |

Evaluate specific AI tools | Pick tools that match business goals, such as robotics or forecasting. |

Note: Start with a small project to learn and show results before doing more.

Building an Implementation Roadmap

A good plan helps teams know each step. First, they check if they are ready. Next, they set goals and pick a test project. Teams try the project, check results, and grow if it works. Managers keep watching how AI works and make changes if needed. The table below shows the steps:

Step | Description |

|---|---|

Readiness Assessment | Check data, systems, and team skills. |

Strategy Development | Set goals and success measures. |

Pilot Selection | Pick a project with big impact. |

Implementation and Testing | Run the pilot and measure results. |

Scaling and Integration | Grow successful projects and connect with other systems. |

Continuous Monitoring | Review performance and improve over time. |

Teams do better by keeping goals simple, starting small, and training workers. They plan for updates and make sure new tools work with old ones. Good planning and teamwork help warehouses get the most from AI.

AI makes warehouse work better by lowering mistakes and saving money. It also helps orders get done faster. The table below shows how much things can improve:

Benefit | Measurement |

|---|---|

Order Picking Time | |

Labor Costs | Up to 60% reduction |

Operational Efficiency | 99% fewer errors |

Managers can try AI with small projects first. They can add more as they see good results. In five years, robots, cloud data, and smart guessing will change even more. Teams do better by always learning and using real examples. This helps them stay ahead.

FAQ

What is AI in warehouse management?

AI in warehouse management uses smart computer programs to help with tasks like sorting, tracking, and planning. These systems learn from data and help teams work faster and make fewer mistakes.

How does AI improve inventory accuracy?

AI checks inventory levels in real time. It predicts what products will sell and alerts teams when stock runs low. This helps companies avoid running out of items or having too much extra stock.

Is AI hard for warehouse workers to use?

Most AI tools have simple screens and clear steps. Companies train workers to use new systems. Many workers find AI makes their jobs easier and less stressful.

What are the main benefits of using AI in warehouses?

Benefit | Description |

|---|---|

Faster Orders | Orders get filled quickly. |

Fewer Mistakes | AI helps avoid errors. |

Cost Savings | Companies spend less money. |

Can small warehouses use AI?

Small warehouses can start with basic AI tools. They can add more features as they grow. Many AI solutions work for both small and large teams.

See Also

Revolutionizing Online Store Management With AI-Driven Tools

The Future of Retail Lies in AI-Enhanced Stores

Essential Insights for Retailers on AI-Driven Corner Stores

Modern Retail Benefits from Features of AI-Enhanced Vending Machines