How Digital Twin Technology Streamlines Warehouse Automation in 2025

Digital twin technology is making warehouses work differently in 2025. Companies use virtual models to watch how things move and try out ideas before they change anything.

Warehouses can be up to 30% more efficient and have up to 50% less downtime.

The worldwide market for digital twins in logistics might go from USD 1.9 billion in 2025 to USD 18.7 billion by 2035.

Warehouses of all sizes get help from real-time data. They use resources better and manage risks more safely.

Key Takeaways

Digital twin technology makes warehouses work better by up to 30%. It also cuts downtime in half.

Digital twins give managers real-time data. This helps them use resources better and make good choices.

Predictive analytics help managers see what is needed soon. They can plan worker schedules well and get more done.

Digital twins help manage risks before they happen. They show possible problems and test fixes without stopping work.

Small and mid-sized warehouses can use digital twin solutions that do not cost too much. This helps them compete and grow.

Digital Twin Technology Benefits for Warehouses

Efficiency and Resource Allocation

Warehouses in 2025 use digital twin technology to work better. This technology makes a virtual copy of the warehouse. It shows how goods move and where workers spend time. Managers can see which jobs take the most effort. They find ways to save time and money. For example, digital twins help leaders choose where to put products. This makes picking and packing faster. They also help plan shifts. Workers are always in the right place at the right time.

"The project made warehouse planners' jobs easier. They could give resources to stations more exactly. This saved working hours and cut costs."

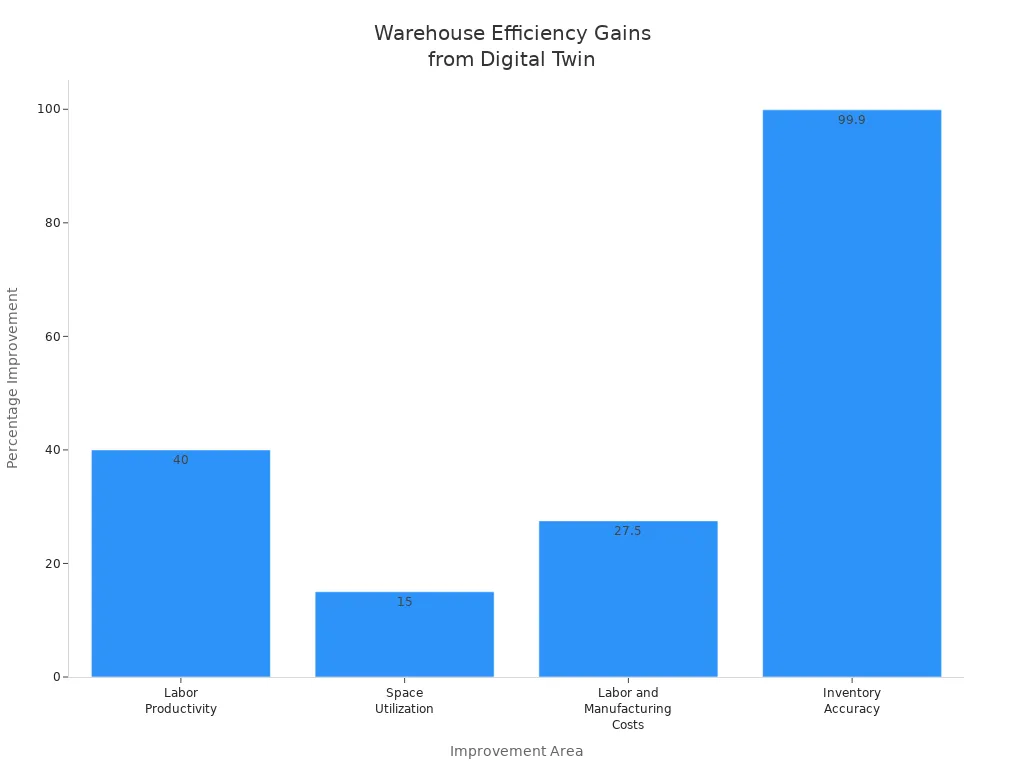

The improvements are easy to see. The table below shows how digital twin technology helps warehouses:

Improvement Area | Percentage Improvement | Source Link |

|---|---|---|

Labor Productivity | 40% | |

Space Utilization | 15% | |

Labor and Manufacturing Costs | 25-30% | |

Inventory Accuracy | 99.9% |

Digital twin technology helps warehouses keep getting better. It collects real-time data. It uses machine learning to guess what workers will need. This helps warehouses use robots and sensors. Operations run smoothly.

Bottleneck Identification and Process Improvement

Digital twin technology gives managers a clear look at warehouse work. They can spot slow spots and fix them before trouble starts. For example:

Managers can try different ways to organize products. They see which way works best.

They use the digital twin to find places where workers or machines wait too long.

Real-time views let leaders change workflows fast to stop delays.

Warehouses using digital twins process orders faster and make fewer mistakes. Customers are happier because orders come on time and have the right items. Some warehouses use digital twins to reroute shipments if there is a problem. This keeps deliveries on track.

Cut downtime by predicting problems and fixing them early.

Make faster decisions using data, so leaders can react quickly.

Digital twin technology helps warehouses keep improving. It shows what works and what does not. It helps make better layouts, accurate inventory, and smarter choices every day.

Risk Simulation and Proactive Management

Warehouses face many risks, like cyberattacks and supply chain problems. Digital twin technology helps managers get ready for these risks by testing different situations. Some common risks are:

Data interception and theft

Model manipulation

Denial of service (DoS) attacks

Ransomware attacks

Supply chain attacks

Managers use digital twins to test "what-if" situations. They can see what happens if a machine breaks or if a cyberattack hits. This helps them make plans to keep the warehouse working, even during problems.

Handle tough times and changes with a steady workforce by making workflows better.

Use real-time checks to react fast to problems.

Test different situations to improve performance without stopping real work.

Digital twin technology helps cut downtime. It uses real-time data to spot problems early. It helps managers make quick choices. This keeps warehouses safe and working well, even when things go wrong.

What Is a Warehouse Digital Twin?

Virtual Model and Key Features

A warehouse digital twin is a virtual copy of the real warehouse. Managers use this model to see how things work. They can test ideas without changing the actual warehouse. They try new layouts and see what happens first.

Key features of a warehouse digital twin are:

It copies the whole warehouse for close study.

It shows how changes affect work and helps with automation.

It lets managers test different worker setups and equipment use.

It gives 3D views of how goods and workers move.

It helps plan for the future and use resources well.

A digital twin lets managers try new things safely. They can test new automation or shift plans and see results fast. This helps them make smart choices and avoid mistakes that cost money.

Managers use these features to make the warehouse better. They find problems, fix slow spots, and make good choices about automation.

Real-Time Data and System Replication

A digital twin works well because it uses real-time data from the warehouse. Sensors and scanners send updates to the digital twin. This keeps the model correct and current.

Real-time data means managers always know what is happening.

Automatic tracking gives quick updates on stock levels.

The digital twin shows where items are and how fast orders move.

Digital twin technology works with warehouse management systems to help things run better. Some solutions make picking routes shorter, which saves walking time by half. Managers can test new layouts in the digital twin before changing the real warehouse. This saves time and lowers risk.

With real-time system copying, managers find problems early and fix them fast. This makes orders go out quicker and customers happier.

A warehouse digital twin helps companies use resources well, spend less, and keep things running smoothly.

Optimizing Automation with Digital Twin Technology

Real-Time Simulation and Monitoring

Warehouse managers use real-time simulation to make work easier. They look at virtual models and test changes before doing them for real. This helps them find the best ways to move goods and stop slowdowns. Managers watch how equipment works and spot problems early. They fix issues before they cause delays.

The table below shows how real-time simulation and monitoring help warehouses:

Benefit | Description |

|---|---|

Virtual testing finds the best ways to work and stops wasted time. | |

Predictive Maintenance | Watching equipment helps managers find problems early and save money. |

Improved Inventory Management | Real-time views of inventory help keep track and use space better. |

Cost Reduction | Managers save money by changing layouts and using resources wisely. |

Enhanced Decision-Making | Simulating different ideas helps managers pick the best plans and lower risks. |

Managers use these tools to keep warehouses working well and make smart choices every day.

Predictive Analytics for Operations

Predictive analytics help managers plan ahead. They use data from past work to guess what will happen next. This helps them schedule workers, order supplies, and keep equipment working. Managers track inventory in real time and see where products go. They test new layouts and find ways to use space better.

Digital twins give managers a clear view of inventory and product movement.

This helps them keep stock levels right and avoid running out.

Managers try different inventory plans and see what works best.

Managers also use predictive analytics to make worker schedules. They look at past data to see when the warehouse is busiest. They use this information to put the right number of workers on each shift. This helps avoid having too many or too few workers.

Predictive analytics study old data to find worker trends.

Managers use digital twin simulations to guess labor needs.

This helps improve worker productivity and avoid mistakes.

The table below shows how predictive analytics help warehouse operations:

Benefit | Description |

|---|---|

Real-time monitoring | Managers spot problems as they happen and fix them fast. |

Simulation capabilities | They test new layouts and product setups to find the best way. |

Predictive maintenance | Managers use data to guess equipment problems and stop downtime. |

Improved inventory management | Tracking inventory helps process orders faster and manage stock better. |

Space utilization optimization | Managers use space wisely and make work more efficient. |

Workforce management | Real-time data helps managers give jobs and use resources well. |

Workflow optimization | Managers find and fix problems quickly to keep work moving. |

Proactive scheduling | They change staffing based on guesses and performance. |

Picking optimization | Predictive algorithms help workers walk less and pick items faster. |

Slotting and storage optimization | Managers test different storage plans to make picking easier. |

Inventory accuracy | Computer vision helps keep inventory data correct and customers happy. |

Continuous process improvement | Managers test changes before using them to keep making work better. |

AI-Driven Recommendations

Artificial intelligence gives managers advice to make warehouses work better. AI studies data from the digital twin and finds ways to improve efficiency. It sends alerts when something goes wrong and suggests fixes. Managers see where workers spend time and how to use labor better.

The table below shows how AI-driven recommendations help warehouse automation:

Role of AI-Driven Recommendations | Role of Digital Twin Technology |

|---|---|

Makes a virtual copy of the warehouse for better work | |

Provides real-time monitoring | Lets managers see work without stopping anything |

Improves accuracy and reduces errors | Finds and fixes problems right away |

Enhances workforce productivity | Tracks how workers use their time and work |

Offers proactive alerts and insights | Sends quick messages for problems |

AI helps managers make fast decisions and keep warehouses working well. It finds problems quickly and helps fix them before they get worse.

Managers use digital twin technology and AI together to make warehouses safer, faster, and more reliable. They test new ideas, plan ahead, and keep making things better every day.

Results and Case Examples

Performance Metrics and Cost Savings

Warehouses check how well they do by looking at time, money, and space. Many warehouse managers say new technology helps a lot. They see less overtime and use space better. There are fewer inventory mistakes and orders go out faster.

The table below shows how much warehouses save after using new tools:

Metric | Savings Percentage/Time Saved |

|---|---|

Time saved on cycle counts | |

Cost reductions in procurement | 3% to 6% |

Reduction in transportation costs | Up to 10% |

Overall departmental cost reduction | 20% to 30% |

Managers use these numbers to make plans and set goals. Saving time on cycle counts lets workers do other jobs. Lower transportation costs help goods get delivered faster. Cost savings in procurement help managers buy supplies better. All these changes help warehouses work well and spend less.

Real-World Warehouse Success Stories

Many small and medium warehouses share stories about new tools helping them. Here are some examples:

Operators handle busy times and tough orders with the same team. They use real-time views to see what is happening and make quick choices.

Teams help machines work better. They watch equipment and fix problems before work stops. This keeps automated systems running and cuts downtime.

Managers say they feel sure about their work. They always know what is going on. They use data to make smart choices and keep customers happy. These stories show even small warehouses can get big benefits from new technology.

Accessibility for All Warehouse Sizes

Solutions for Small and Mid-Sized Warehouses

Small and mid-sized warehouses can use new tools now. Many companies sell systems that are not expensive. These systems help small businesses grow and compete. Picking the best system is very important. Some options are easy to move and can grow with the warehouse. Cloud-based inventory systems help warehouses get bigger without starting over. These systems get updates easily and have support.

Working with a company that knows new technology helps a lot. These partners help save money and make learning easier. Here are ways small warehouses can begin:

Use low-cost technology to make work better and earn more.

Pick good systems that can grow with your warehouse.

Choose cloud inventory tools for easy updates and access.

Work with skilled logistics companies to save money and learn faster.

Tip: Begin with a few features and add more later. This keeps costs low and makes changes easier.

Overcoming Technical Barriers

Warehouses have problems when they use new technology. These problems can slow things down. Knowing about them helps managers plan well. The table below shows common problems and how they affect warehouses:

Barrier Type | Description |

|---|---|

Ensuring Data Quality | Good data keeps systems working right. Bad data causes mistakes. Rules for data are needed. |

New systems cost a lot at first. Small warehouses must plan their money. | |

Training and Skill Development | Workers need training for new systems. This takes time and money, so planning is important. |

Cybersecurity Risks | New systems use lots of important data. Strong security keeps data safe. |

Managers can beat these problems by starting simple. They should use good data and train workers well. Checking security often helps keep the warehouse safe.

Digital twin technology gives warehouses strong tools for automation. The table below lists the main benefits:

Advantage | Description |

|---|---|

Predictive Maintenance | Finds equipment problems early and stops breakdowns. |

Security Management | Tests for security problems and finds weak spots. |

Operational Optimization | Watches work as it happens and helps managers choose well. |

Cost Reduction | Helps make choices that save money. |

Improved Customer Service | Answers customer needs faster. |

Increased Performance | Makes work faster and more productive. |

Warehouses use digital twins to watch data and make smart choices. This technology helps them keep up in a market that changes fast. AI and IoT make digital twins even better, so managers can change plans quickly.

Retailers use less energy and help the planet.

Warehouses make less pollution from trucks and machines.

Managers who use digital twin solutions help their warehouses stay ahead in 2025.

FAQ

What is a digital twin in a warehouse?

A digital twin is a virtual copy of a warehouse. It shows how goods move and where workers go. Managers use it to try new ideas. They can make changes without touching the real warehouse.

How does digital twin technology help reduce warehouse costs?

Digital twin technology helps managers save money. They use it to plan better layouts and stop mistakes. It helps avoid downtime and lowers labor costs. Transportation costs also go down.

Can small warehouses use digital twin technology?

Small warehouses can use digital twin technology too. Many companies sell affordable systems. Cloud-based tools help small teams grow. They can compete with bigger businesses.

What risks can digital twins help manage?

Digital twins help managers get ready for risks. These risks include equipment failure and cyberattacks. They also help with supply chain problems. Managers test different plans to keep things safe.

How does real-time data improve warehouse automation?

Real-time data shows what happens in the warehouse right now. Managers use this data to fix problems fast. They track inventory and make better choices.

See Also

The Future of Retail Lies in AI-Driven Stores

Upcoming Changes to Walmart Self-Checkout Systems in 2025

Automated Vending Machines: The Next Era of Fast Food

Transforming Online Retail Management with AI E-Commerce Tools

Smart Technology in Vending Machines Revolutionizes Retail Experience