Breaking Down the Expenses and ROI of Digital Warehouse Maintenance

Managing technology costs in a warehouse can be hard. Many leaders have to make hard choices when they see the cost of digital warehouse maintenance. They want to know if spending money will really help them. Checking the return on investment helps them make clear goals. It also helps them watch important numbers and ask experts for help.

When they know both the costs and possible gains, they can make better choices and help their teams do better.

Reason for Evaluating ROI | Explanation |

|---|---|

Optimizing Operations | Knowing ROI helps make work easier and faster. |

Reducing Costs | Finding money benefits can help save money. |

Improving Customer Satisfaction | Better systems give better service and make customers happier. |

Key Takeaways

Knowing the costs of digital warehouse maintenance helps leaders choose wisely and plan well.

Doing regular maintenance and updates stops bigger problems. This keeps things running smoothly and protects what you own.

Checking ROI means adding up all costs and benefits. This helps leaders make clear goals and help teams do better.

Teaching workers about new systems makes them feel sure. It also lowers mistakes and makes the warehouse work better.

Watching for hidden costs and planning upgrades helps control budgets. It also stops surprise costs from happening.

Digital Warehouse Maintenance Costs

Knowing the costs of digital warehouse maintenance helps leaders plan well. Every warehouse has its own problems, but learning about the main costs gives everyone a good place to start. When teams look at these costs, they can make smart choices and get ready for the future.

Initial Investment

The first part of digital warehouse maintenance needs a big first payment. This means buying and setting up technology, equipment, and automation systems. The price changes based on the kind and size of the system.

Cloud-based warehouse management systems (WMS) usually have a starting fee from $1,000 to $7,000.

On-premises WMS setups can cost $2,000 to $10,000 just to start.

RFID-based WMS solutions cost between $2,000 and $10,000.

Automation systems, like picking or machine systems, can cost $500,000 to $5 million. Big company systems can cost up to $15 million, and fully automated "dark warehouses" can cost about $25 million.

Picking the right technology at the start helps the warehouse grow and work better for a long time.

A medium-sized warehouse usually has a few main starting costs:

Description | |

|---|---|

Equipment Costs | Buying and fixing equipment like forklifts and conveyor belts needed for the warehouse. |

Storage and Inventory Costs | Paying for space and the items stored there. |

Labor Wages | Paying workers like pickers and packers. |

Paying for technology like warehouse management systems. | |

Shipping and Transportation Costs | Paying to ship goods and for transport. |

Annual Maintenance Expenses

After the first setup, digital warehouse maintenance needs yearly spending. These costs help keep systems working well and make sure technology stays new.

On-premises WMS often have yearly fees that are 10-15% of the first software price. For example, a $75,000 license means $7,500 to $11,250 each year.

Cloud-based systems usually include fixes, help, and security in their monthly or yearly fees. These can be $1,000 to $5,000 each month, depending on what you need.

Automated systems may need 15-20% of the first cost each year for care. This pays for updates, testing, and training workers.

Spending on regular care stops bigger problems and keeps the warehouse working well.

If the system is more complex, the yearly costs can go up. More advanced automation or connecting to other business tools can make the budget higher. Leaders who plan for these costs do not get surprised and keep their warehouse strong.

Hidden and Upgrade Fees

Some digital warehouse maintenance costs are not easy to see at first. Hidden fees and upgrade costs can surprise even skilled managers. Knowing about these costs helps teams get ready and stay in control.

Cost Range | |

|---|---|

Making new integrations | $20,000 - $60,000 for each one |

Yearly care and checking | $5,000 - $12,000 each year for each integration |

Vendor management costs | $11,000 - $17,000 each year |

Training for each new worker | $1,470 for each worker |

Total yearly costs you can see | $282,600 |

Upgrade fees are important too. These costs keep warehouse management systems up to date and safe. The price depends on how tricky the system is and how often it needs updates. Some upgrades are small and come with a subscription, but others cost more.

Cloud WMS often include upgrades, bug fixes, and security in the fee, so costs are easier to guess.

On-premises WMS may need extra money for updates, fixes, and repairs. Yearly repair costs can be $5,000 to $20,000, with more charges for big upgrades.

When leaders know about all the costs, they can plan ahead and stop problems before they start.

Key Services in Maintenance

Software Updates & Security

Software updates and security patches help keep systems safe. Teams need to act quickly when new threats show up. Important security patches should be added within 30 days. Less important updates can wait up to 90 days. Big warehouses often use tools to check for updates every day or twice a week. Small teams might update their software every week or every other week.

Recommendation | Frequency |

|---|---|

Critical security patches | Within 30 days |

Non-critical updates | Within 90 days |

Keeping up with updates protects important data and helps work go on.

Technical Support

Good technical support helps teams fix problems fast. Most support teams answer urgent questions in 2 to 4 hours. Quick help means less waiting and fewer slowdowns. Service level agreements set clear rules for how fast teams should respond. Fast support makes teams feel ready to do their best.

Support teams answer critical problems in 2-4 hours.

How fast they answer can change if the problem is bigger.

System Integration

System integration links all parts of the warehouse together. Teams have to make sure data is right, connect with other systems, and test before using new tools. Good integration means less manual work and saves money. It also helps teams see inventory clearly and stop mistakes.

Challenge Type | Description |

|---|---|

Data Accuracy | Making sure data stays right during integration. |

Integration with Third-Party Systems | Making sure systems work together. |

Comprehensive Testing | Testing everything to stop problems later. |

User Training | Showing users how to use new systems. |

Integration brings new tools together, making the warehouse work better and smarter.

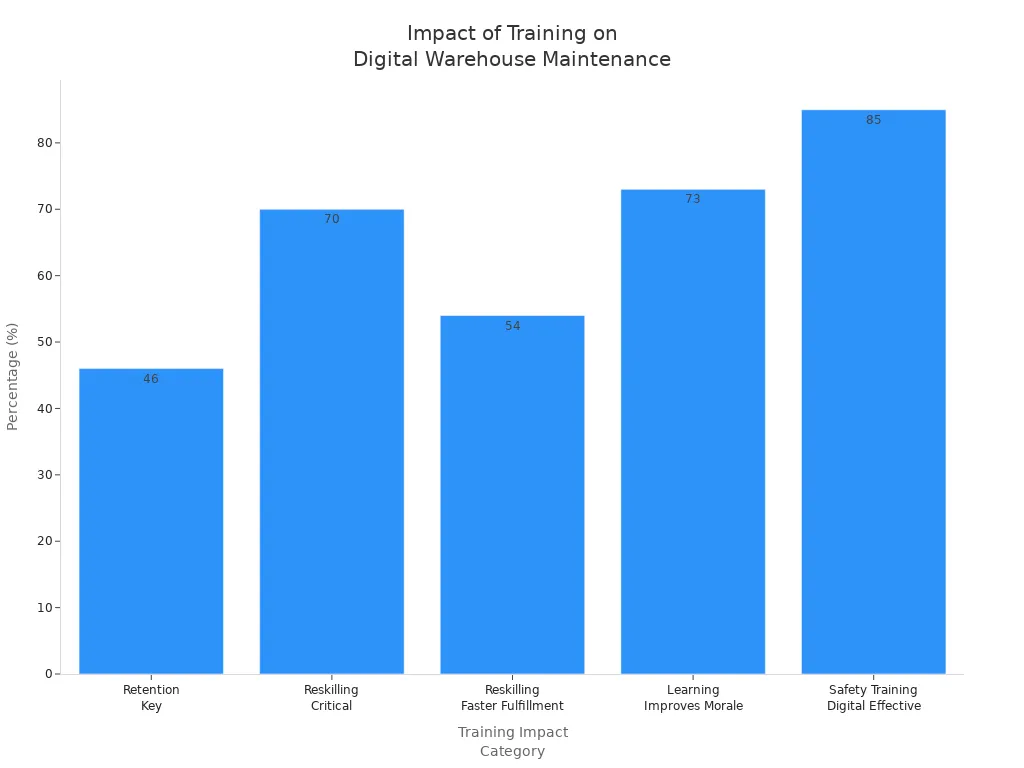

Training

Training teaches workers how to use new tools and stay safe. Most training lasts 6 to 8 weeks. It costs about $4,500 to $6,000 to hire and train a worker. Ongoing training keeps teams ready for changes. Many managers think reskilling and learning new things help teams feel good and fill orders faster.

Training makes teams strong so they can handle any problem in digital warehouse maintenance.

ROI Evaluation for Digital Warehouse Maintenance

ROI Calculation Steps

Checking the return on investment helps warehouse leaders make smart choices. They start by figuring out all costs and benefits for digital warehouse maintenance. This helps them see everything and set clear goals.

Guess the costs and benefits for the warehouse management system.

Find every cost and benefit, like saving labor and better accuracy.

Collect data and ask experts for good guesses.

Figure out the project’s cash flow for three to five years.

Think about changes in cash flow from inflation or higher wages.

Leaders who use these steps feel sure about their choices and help their teams do better.

The basic ROI formula is:

ROI = (Net Annual Benefits / Total Implementation Costs) × 100%

For example, if a warehouse saves $100,000 each year and spends $200,000 to set up the system, the ROI is 50%. This easy math shows how fast the investment pays off.

Financial Metrics (Payback, NPV, IRR)

Warehouse managers use different financial metrics to check success. These numbers show how fast they get results and how strong their investment is.

Metric | Description |

|---|---|

Payback Period | Total Implementation Cost ÷ Annual Net Savings. Most systems pay for themselves in 12-24 months. |

Net Present Value (NPV) | Finds the present value of savings over 3-5 years. A positive NPV means the investment is smart. |

Internal Rate of Return (IRR) | The discount rate where NPV equals zero. Most IRRs for warehouse systems are 25-50%. |

Managers also look at ROI and ROCE. ROI shows how much profit the investment makes compared to its cost. ROCE shows how well the warehouse uses all its money to make profit. These metrics help leaders aim for better returns and encourage teams to work together.

Tangible & Intangible Benefits

Digital warehouse maintenance gives many benefits that are more than just numbers. Some gains are easy to measure, while others help team spirit and make customers happier.

Tangible Benefits:

Automation makes work faster and better by using real-time data for inventory.

Orders are more accurate and quick, so customers are happier.

Labor savings grow because automation does more work.

Fewer mistakes mean less money spent fixing problems and returns.

Benefit | Description |

|---|---|

Improved Efficiency | Automation makes things faster and cuts mistakes. |

Enhanced Accuracy | Automated systems do tasks right, so there are fewer picking errors. |

Cost Savings | Lower labor costs and fewer mistakes save money. |

Scalability | Automated systems help warehouses grow without needing more workers. |

Intangible Benefits:

Workers feel happier, so fewer leave and less money is spent hiring.

Customer service gets better with clearer data and faster answers.

Teams work together more, sharing info and solving problems.

Happy workers help customers feel special and keep orders moving.

Real-time analytics help managers make smart choices and react to changes.

When leaders care about both tangible and intangible benefits, they build a good place to work that helps everyone succeed in the warehouse.

Factors Affecting Costs & ROI

Warehouse Size & Complexity

The size and shape of a warehouse changes how digital maintenance works. Bigger warehouses need more automation parts, so they cost more. If the work is complicated, the systems must be smarter and need more planning. Leaders know that bigger spaces cost more at first, but these costs can save money and make work easier later.

Factor | Impact on Costs & ROI |

|---|---|

Warehouse Size | Larger spaces need more automation, so costs go up. |

Workflow Complexity | Harder jobs need better systems. |

Existing Infrastructure | Old systems might need to be updated. |

Desired Automation Level | More automation means spending more at the start. |

Automated systems change how people work every day. They cost more at first, but help teams work faster and make fewer mistakes. These changes help managers set bigger goals and get better results.

Technology Level

New technology helps warehouses do better. Advanced tools make work faster, more correct, and flexible. Teams use robots to do jobs, which saves money on workers and makes orders go out faster. IoT devices watch energy use, so managers can spend less and save power.

AI can find machine problems before they get worse.

Sensors can stop machines from breaking down.

Automation helps stop mistakes and saves money.

Smart devices help teams make quick choices and change plans.

Each new tool gives more chances to improve. Leaders who buy smart tools see their teams get better and more sure of themselves.

Integration Needs

Connecting warehouse systems makes them stronger. Linking with TMS and WMS saves money on shipping and makes work smoother. Teams share data and fix problems faster. Customers see the difference when orders come on time and service gets better.

Connecting systems can save 5 to 10% on shipping.

Good links make work faster and cost less.

Sharing data helps teams work together.

Better ways of working make customers happier.

Managers who focus on connecting systems help their teams do well for a long time.

Long-Term Value

Digital maintenance gives more value every year. Smart spending on automation and technology lowers costs, helps teams do more, and makes people happier. Leaders see that every upgrade and training makes the warehouse stronger. They help their teams reach new goals and celebrate every win.

Spending money on digital warehouse maintenance is not just for now. It helps build a future where every worker feels proud and every customer trusts the warehouse to do a good job.

Maximizing ROI

Cost Control Tips

Warehouse leaders can do smart things to save money. They check spending often and look for ways to cut costs. Teams make clear budgets for each part of the warehouse. They watch every dollar and stop waste before it gets big. Leaders compare prices from different vendors to get good deals. This helps them buy equipment and software for less money. Training and skill checks help workers make fewer mistakes and work faster. When everyone knows how to use the system, the warehouse works well.

Small changes in how money is spent can save a lot over time.

Performance Optimization

Teams do better when they focus on working well. Upgrading and growing the WMS keeps the system strong as the business gets bigger. Leaders use reports and data tools to see how things are going. These tools show where work is slow or mistakes happen. Teams fix problems fast and celebrate when things go right. They set new goals and try to do better each month. When everyone helps, the warehouse becomes a place where people are proud to work.

Optimization Strategy | Benefit |

|---|---|

Upgrade WMS | Handles more orders |

Use analytics | Finds slow spots |

Regular training | Fewer mistakes |

Regular ROI Review

Checking ROI often helps leaders stay on the right path. They see if digital warehouse maintenance gives the results they want. Teams look at savings, speed, and how happy customers are. If something is not working, they change what they do. Leaders share results with everyone, so the team feels proud. Checking often keeps everyone working toward success.

Every review is a chance to learn, get better, and reach new goals.

Smart leaders look at each cost and check the return. They write down all costs and see what benefits are real. They use easy numbers to help make choices. Now is a good time to look at your warehouse costs and returns.

Take action: Make clear goals and watch your savings. Teach your team and check your plan often. Each step helps your warehouse get better and grow. 🚀

FAQ

What is digital warehouse maintenance?

Digital warehouse maintenance is about keeping technology working well. Teams check software often and update tools when needed. They fix problems fast to keep things running. This helps the warehouse work smoothly and keeps people safe.

How can leaders measure ROI for warehouse technology?

Leaders use easy math to check ROI. They see how much money they save and how much they spend. They also look at faster work, fewer mistakes, and happy customers. This shows if the investment is worth it.

Why does training matter in digital warehouse maintenance?

Training helps teams learn new skills and feel sure of themselves. Workers make fewer mistakes and help the warehouse do well. When everyone knows the system, leaders see better results.

What hidden costs should managers watch for?

Managers need to look out for upgrade fees, extra training, and integration costs. These costs can surprise teams if they are not ready. Planning ahead helps leaders stay in control and protect their money.

See Also

Understanding Vending Machine Expenses: Features, Types, and Returns

The Impact of AI Tools on E-Commerce Store Operations

Enhancing Employee Efficiency with Intelligent Vending Machines

Modern Retail Benefits from AI-Enhanced Combo Vending Machines