Step-by-step Guide for imploying IoT and Data Analytics for Warehouse Efficiency

Warehouses need quick updates and smart machines to keep up. IoT sensors watch inventory all the time. Data analytics finds patterns that help workers do better. Many warehouses use these tools to make work safer. They help lower mistakes and find equipment problems early. This stops delays from happening.

Improvement Type | Description |

|---|---|

IoT sensors give live stock updates. This stops shortages or too much stock. | |

Predictive Maintenance | Sensors find equipment problems early. This means less downtime. |

Enhanced Operational Efficiency | Devices talk to each other to make tasks easier. They help cut down on mistakes. |

Key Takeaways

Put IoT sensors in the warehouse to track inventory all the time. This stops you from running out of stock or having too much.

Make clear goals for IoT and data analytics projects. Try to make things work better, spend less money, and manage inventory well.

Get all important people to join in the process. Working together helps find problems early and gets everyone to support new systems.

Pick sensors that fit what your warehouse needs. Make sure they work with your current systems so you do not have problems connecting them.

Look at data often to spot patterns and trends. Use what you learn to make smart choices and help the warehouse run better.

Assess Warehouse Needs and Set Goals

Identify Inefficiencies and Pain Points

Warehouse managers deal with problems that slow work down. Old inventory tracking systems can make things confusing. Mistakes happen more often with these systems. Picking orders by hand takes a lot of time. This can cost almost half of all order processing money. Many warehouses use old systems that do not work well with new technology. Some staff do not want to change how they work. Projects can cost more than planned or take longer to finish.

Issue | Percentage Impact |

|---|---|

Inefficiencies from outdated inventory tracking systems | |

Cost of order picking processes | Up to 50% |

WMS projects with budget overruns or schedule delays | 60% |

IoT solutions help fix these problems. Automated item tracking uses sensors to watch goods move in and out. Smart shelves show managers where items are and when to restock. Robots can move racks to use space better. Sensors also check the warehouse environment. They alert managers if something needs fixing.

Define Objectives for IoT and Analytics

Setting clear goals helps warehouses use IoT and data analytics well. Managers should pick what they want to improve. This could be faster order picking or better inventory accuracy. Goals can include lowering costs, making work smoother, or reducing mistakes.

Specific Objectives | Impact on Warehouse Performance |

|---|---|

Improving efficiency | Makes work faster and saves time. |

Reducing operational costs | Helps spend less money by using resources better. |

Enhancing inventory management | Makes tracking more accurate and cuts mistakes. |

Clear goals help guide the project and keep everyone focused. Matching these goals with the company’s big plans makes changes work better.

Involve Key Stakeholders

Warehouse changes work best when everyone helps. Managers, IT staff, and workers should share ideas and worries. Getting key people involved helps find problems early. It also builds support for new systems. Staff can say what works and what does not. Working together makes it easier to handle changes and teach everyone new tools.

Tip: Have regular meetings with everyone to check progress and fix problems fast.

Choose IoT Sensors and Devices

Select Sensors for Inventory and Asset Tracking

Warehouses need sensors to help track items and assets. These sensors show managers where things are all the time. Some sensors work better for certain jobs.

RFID tags help track where assets are and how many there are.

GPS tracking shows where things are right now. This is good for big or far-away warehouses.

Bluetooth Low Energy sensors help track things in small spaces.

Electronic tags help track items and assets automatically.

IoT gateways collect signals from BLE tags and record where assets are.

Some warehouses use satellite and GPS tracking for far-away places. Others use cellular tracking like 4G or 5G for bigger areas. LPWAN technologies such as NB-IoT and LTE-M are cheap and work over long distances.

Tip: Managers should pick sensor types that fit their warehouse size and layout for the best results.

Monitor Environmental and Equipment Conditions

Sensors do more than just track items. They also watch the warehouse and equipment. This helps keep goods safe and machines working well.

Temperature and humidity sensors keep sensitive products safe.

PIR sensors find movement and help with security.

Water leak sensors warn managers before damage happens.

Door and window sensors show if entry points are secure.

IoT hubs connect many sensors for easy control.

Smart plugs let managers turn equipment on or off from far away.

Vibration sensors check if machines are working right.

BLE beacons help track where equipment and staff are.

These devices help managers find problems early and keep the warehouse safe.

Ensure Device Compatibility

Device compatibility is important when adding new sensors to old systems. Different devices may use different ways to talk to each other. Managers can fix these problems in a few ways:

Challenge | Solution |

|---|---|

Systems that do not use the same protocols | Use gateways and protocol converters to connect them. |

Old equipment that does not use new protocols | Pick devices that use open standards like MQTT, CoAP, and OPC UA. |

Hard to connect devices from different vendors | Use middleware to help devices talk and share data. |

Note: Picking devices that use open standards makes upgrades easier and helps avoid problems later.

Integrate Systems and Ensure Data Flow

Connect IoT Devices to Warehouse Management Systems

Warehouses need good links between IoT devices and management systems. This helps data move fast and stay safe. Managers should follow some steps to keep data flowing well:

Use storage that can grow and hold lots of data.

Use real-time analytics and edge computing for quick data.

Pick data lakes and smart systems for many data types.

Check data for mistakes with regular audits.

Store data in NoSQL or time-series databases for easy scaling.

Make a security plan with encryption and updates.

Build systems with privacy and use data anonymization.

Make data easy to get with cloud storage and simple tools.

Mix data from different places using ETL tools and APIs.

Use machine learning and predictive analytics to find patterns.

Tip: Managers should test device connections before using them every day.

Address Data Security and Privacy

Security and privacy are important when using IoT in warehouses. Many risks can happen if managers do not protect data. The table below shows common problems and what they mean:

Challenge | Description |

|---|---|

Lack of encryption | Attackers can steal data if it is not encrypted. |

Poor network security and segmentation | Attackers can reach the whole network through weak devices. |

Limited visibility of security breaches | Managers may not see attacks because there are too many devices. |

Sophisticated malware threats | Advanced malware can hide and attack weak devices. |

Outdated software and firmware | Old software can have security holes. |

Limited device resources | Some devices cannot run strong security programs. |

Privacy concerns | Collecting lots of data can risk sharing or misuse. |

Inconsistent standards and regulations | Different rules make it hard to keep all devices safe. |

Note: Managers should update software often and use strong passwords to protect data.

Plan for Scalable Integration

Warehouses need to plan for growth when adding IoT devices and analytics. The steps below help managers build systems that can grow:

Step | Description |

|---|---|

Define clear objectives | Managers set goals and check progress. |

Assess existing systems | See if current systems can handle new data. |

Select the right devices | Pick sensors that fit warehouse needs. |

Start small with a pilot | Try new tools in one area first. |

Secure data and networks | Use encryption and strong passwords. |

Plan for scalability | Build systems that can add more devices. |

Train staff | Teach teams to use new tools. |

Iterate and improve | Watch data and change workflows as needed. |

Tip: Managers should check system performance often and make changes to support more devices.

Deploy and Leverage Data Analytics

Install and Configure IoT Sensors

Putting in IoT sensors is the first step for warehouse data analytics. Managers pick sensors based on what they want to measure. They may want to track temperature, movement, or where inventory is. The sensors must fit the warehouse and the manager’s goals.

Managers plan where to put the sensors. Sensors need to cover all important spots. They must think about how sensors get power and send data. Some sensors use batteries. Others use solar power. Sensors need protection from dust and water.

A device management platform helps managers set up and watch sensors. This platform lets managers check if sensors work and change settings. Here are the steps:

Pick sensors that match what needs to be measured.

Plan where sensors go and how they get power.

Put sensors in safe places and protect them.

Choose how sensors connect and get power.

Decide if sensors use batteries or solar panels.

Use a platform to set up and watch sensors.

Tip: Managers should test each sensor after putting it in to make sure it works right.

Collect and Analyze Real-Time Data

After sensors are set up, warehouses start collecting real-time data. This helps managers see what is happening right now. Special tools and platforms help collect and look at data. The table below shows some ways to do this:

Method | Description |

|---|---|

Streaming Tools | Use tools like Apache Kafka, AWS Kinesis, or Azure Event Hubs for real-time data ingestion. |

Analytics Platforms | Use platforms such as Tableau, Power BI, or Looker for real-time data visualization. |

Real-Time Data Pipelines | Set up pipelines for continuous data flow, using ETL or ELT processes for real-time operations. |

Managers use these tools to watch inventory and equipment. They can see problems as soon as they happen. Data analytics platforms help managers understand the data. These platforms show patterns and trends.

Note: Real-time data lets managers fix problems fast and make the warehouse work better.

Use Analytics for Actionable Insights

Data analytics platforms help managers do more than just look at numbers. They help managers use data to make the warehouse better. Here are the steps:

Collect good data from sensors and other places.

Clean the data and get it ready to use.

Put data from different places together in one model.

Look at the data to find patterns.

Show the data with charts and graphs.

Managers use these insights every day. They can see how many orders each customer has. They can use resources better. They can find orders that have not moved and fix them. Near-real-time updates help managers find slow spots.

Check and update KPIs often to match company goals.

Use analytics to find trends and make small changes for big results.

Tip: Managers should look at analytics results often and share what they learn with the team so everyone can help improve.

Data analytics helps managers make choices based on facts. This means resources are used better, mistakes are fewer, and the warehouse works more smoothly.

Optimize Operations and Overcome Challenges

Streamline Inventory and Space Utilization

Warehouses use IoT and data analytics to work better. Real-time tracking tells managers where items are right now. It also shows how many items are in stock. Automated systems help keep the right amount of stock. These systems lower mistakes. Predictive maintenance keeps IoT devices working well. It stops problems before they slow down work. IoT helps use space in smart ways. Workers can do their jobs faster.

Real-time tracking shows where items are and how many.

Automated systems help keep stock levels correct.

Predictive maintenance stops devices from breaking.

IoT helps use space better and makes work faster.

Tip: Managers should check space layouts often. They should use data to change storage when needed.

Improve Equipment Performance and Maintenance

IoT analytics help keep machines working well. In one big center, managers put IoT sensors on important machines. They used tools to watch machine health all the time. This helped them plan repairs when work was slow. They could order spare parts without waiting. The center had 30% less machine downtime. Efficiency got better.

Address Cost, Security, and Training Issues

Warehouses have problems when using IoT and analytics. High costs, security risks, and needing skilled workers are common.

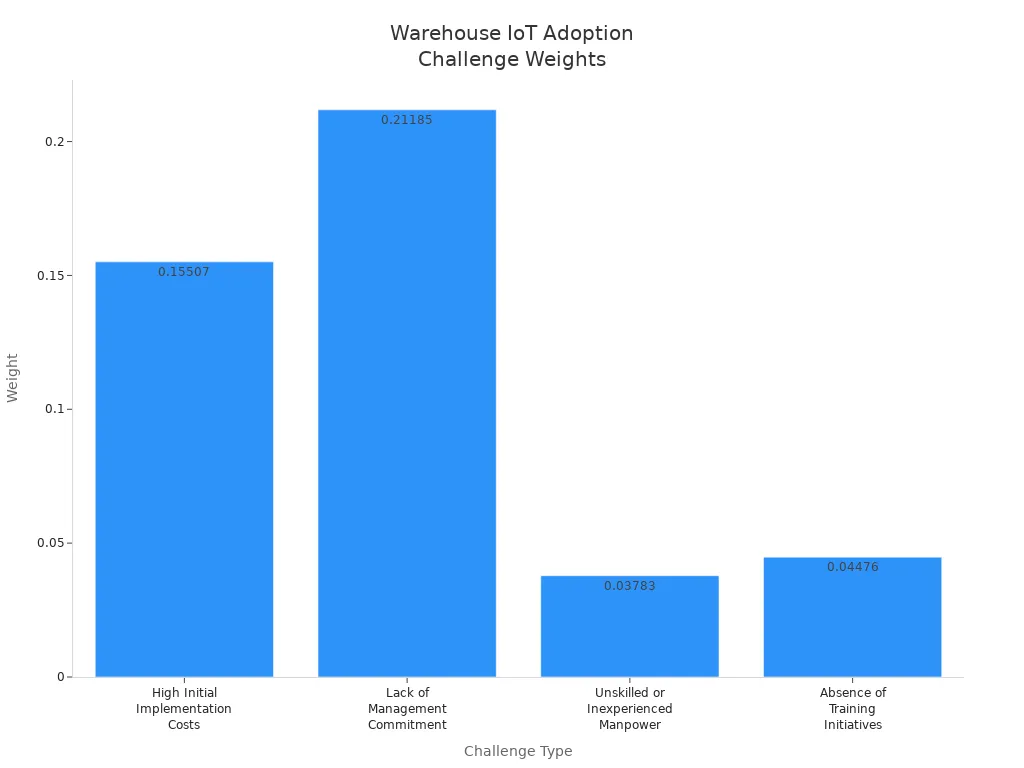

Challenge Type | Description | Weight |

|---|---|---|

High Initial Implementation Costs | Big investment needed for IoT technology. | 0.15507 |

Lack of Management Commitment | No support from top managers for new technology. | 0.21185 |

Unskilled or Inexperienced Manpower | Staff need special training for IoT. | 0.03783 |

Security and Privacy Concerns | More risk of cyberattacks on IoT devices. | N/A |

Absence of Training Initiatives | No training programs for IoT skills. | 0.04476 |

About 25% of IoT devices may face cyberattacks soon. Big companies have more risk for data leaks. Security plans must protect from attacks inside and outside.

To beat cost problems, companies should check ROI. They should look at labor savings, fewer mistakes, and better work. A good plan helps show why the investment is smart. Looking for financing and incentives can lower costs.

Note: Training programs teach staff new skills. This helps the warehouse work well.

Warehouses using IoT and data analytics work better. Managers can watch inventory, make fewer mistakes, and get more done. They should begin with a small test project. First, they need to set simple goals. Next, they use solutions that are already made. Then, they try these tools in real warehouse work. After testing, they make changes to get better results.

Key performance indicators show if things are working well:

KPI | Description |

|---|---|

Inventory Accuracy | Compares records to what is really in stock. |

Order Lead Time | Counts how long it takes to deliver orders. |

Managers should check their systems often and think about growing bigger. Now is a good time to see if the warehouse is ready for IoT and analytics.

FAQ

What is IoT in a warehouse?

IoT means using smart sensors and devices in warehouses. These sensors help track items and watch equipment. They collect data for managers. Managers can see what is happening right now.

How does data analytics help warehouse managers?

Data analytics helps managers find patterns in warehouse data. Managers can see slow spots and fix problems quickly. They use analytics to make better choices. It also helps lower mistakes and make work smoother.

Are IoT systems safe to use?

Most IoT systems use strong security like passwords and encryption. Managers need to update software often. Staff should learn how to keep systems safe. Good security plans help protect data from hackers.

Can small warehouses use IoT and analytics?

Small warehouses can use IoT and analytics too. Many solutions work for big and small places. Managers can start with a few sensors. They can add more sensors as they need them.

What skills do workers need for IoT warehouses?

Workers need to learn how to use new devices and software. Training helps staff read data and fix sensors. It also teaches them to use analytics tools. This helps everyone work together better.

See Also

Revolutionizing Online Store Management With AI-Driven Tools

The Future of Retail Lies in AI-Driven Stores

Understanding The Growth of AI-Enhanced Corner Stores

Launching A Cost-Effective AI-Driven Corner Store Successfully

Enhancing Office Efficiency Through Intelligent Vending Solutions