How Predictive Maintenance Reduces Downtime in AI Store Machines

Predictive maintenance uses real-time data and AI to help your machines work well. It can guess and stop problems before they happen. This means you have fewer breakdowns and less downtime. Your store runs more smoothly. Studies show predictive maintenance can cut downtime by up to 50%. It can also help your machines last longer, as shown below:

Source | Downtime Reduction | Additional Insights |

|---|---|---|

Deloitte | Up to 25% | Companies using sensor-driven predictive maintenance |

McKinsey | Up to 50% | Predictive maintenance can make machines last 40% longer |

General Industry | 35-50% | Less unplanned downtime with predictive maintenance |

With predictive maintenance, you save money. You also make customers happier because your equipment works when needed. Well-kept machines help make the store better for everyone.

Key Takeaways

Predictive maintenance uses real-time data and AI to stop machines from breaking. This can cut downtime by up to half.

Sensors on machines help find problems early. This lets workers fix small issues before they get worse.

Automated maintenance scheduling saves time and money. It plans repairs based on how the machine is working, not just guesses.

AI and machine learning help tell when machines might break. This lets workers fix things on time and helps machines last longer.

Connecting predictive maintenance to current systems makes everything work better. This makes customers happier and keeps the store running smoothly.

Predictive Maintenance Overview

What Is Predictive Maintenance

Predictive maintenance helps you keep your store machines working well. You do not wait for a machine to stop working. Sensors and AI watch for signs that something might go wrong. This way, you can fix problems before they get worse. The table below shows how preventive and predictive maintenance are different:

Aspect | Preventive Maintenance | Predictive Maintenance |

|---|---|---|

Approach | Regularly scheduled maintenance tasks | Data and analytics to predict equipment failure |

Objective | Prevent unplanned downtime, reduce repair costs | Minimize equipment downtime, reduce maintenance costs |

Methodology | Based on predictable lifespan of equipment | Based on monitoring indicators of potential failure |

Maintenance Scheduling | Scheduled based on equipment lifespan | Scheduled based on data analysis and condition monitoring |

Key Advantage | Extends equipment lifespan through regular maintenance | Avoids unnecessary maintenance by understanding actual condition |

Key Disadvantage | May lead to unnecessary maintenance if not accurately timed | Requires investment in data collection and analysis tools |

Sensors give real-time data about things like vibration and temperature. AI looks at this data to find early warning signs. You can then plan repairs at the best time for your store.

Benefits for Store Machines

Predictive maintenance gives your store many good things. You have less downtime because you can plan repairs when the store is not busy. This can make your machines work 20% more of the time. You also save money because you do not need as many emergency repairs or extra parts. AI-powered predictive maintenance helps you fix the right machines at the right time, so your store works better.

Visualization tools make hard data easy to understand. You and your team can make quick choices to keep machines working.

Sensors find small problems early. You can fix them before they get big, so your store keeps running.

Predictive maintenance helps your team work together. Everyone can see the same data and act fast.

Tip: If you connect predictive maintenance to your current systems, your store gets even better. You can use sensor data, let AI check it, and make work orders for your team.

Predictive maintenance is important for AI-powered store machines. It keeps your equipment working, saves money, and makes customers happy. You use AI and predictive models to make smart choices and help your store stay ahead.

AI-Based Predictive Maintenance

AI and Machine Learning

You can use ai-based predictive maintenance to help your store machines work well. AI algorithms and machine learning watch your equipment all the time. These tools look at data from your machines. They find problems before they happen. You do not need to wait for a breakdown. You fix issues early and stop downtime.

Machine learning finds patterns in data. It predicts when a machine might fail.

Ai-based predictive maintenance helps you act before a problem gets worse.

You use data to make smart choices. This keeps your machines working longer.

When you use ai-based predictive maintenance, you have more control over your store. You can plan maintenance when it is best for you. Your machines last longer. You save money on repairs.

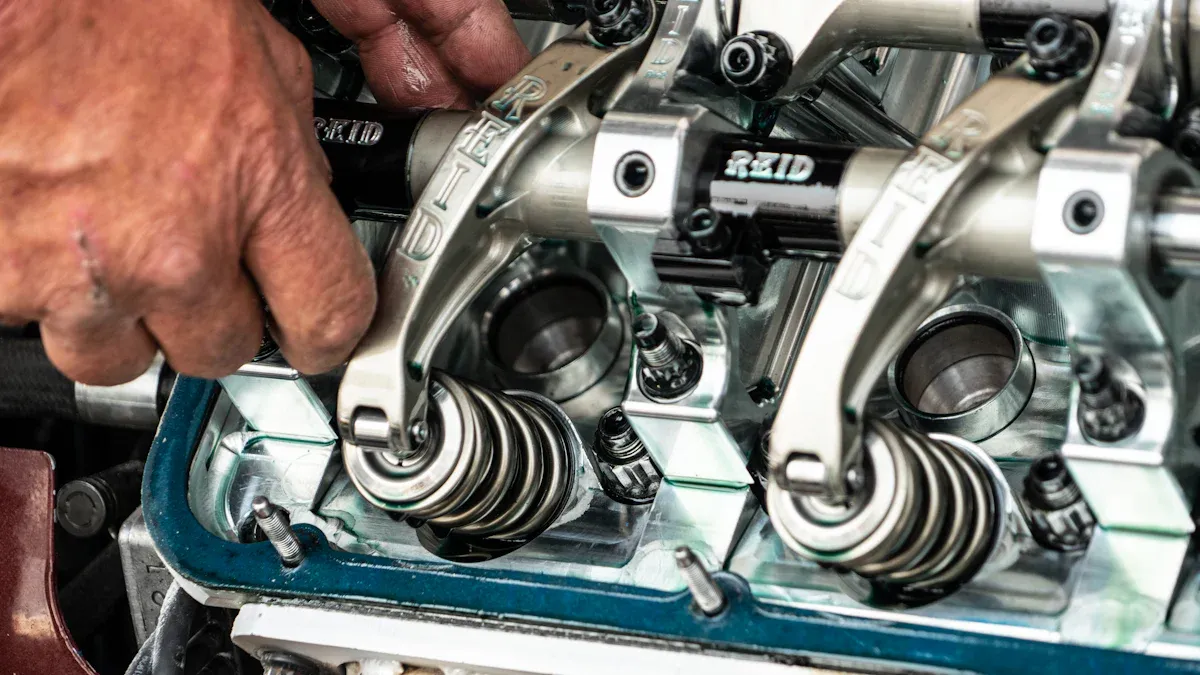

Data and Sensors

Sensors are important in ai-based predictive maintenance. They collect data from your machines every second. You get information about temperature, vibration, current, and voltage. This data helps ai algorithms find small problems before they get big.

Sensor Type | Data Collected |

|---|---|

Vibration Sensor | Equipment vibrations |

Temperature Sensor | Equipment temperature |

Current Sensor | Electrical current |

Voltage Sensor | Electrical voltage |

Vibration sensors help you find worn bearings.

Temperature sensors show if a machine is too hot.

Current sensors let you check load conditions.

Voltage sensors make sure your machines get the right power.

Ai-based predictive maintenance uses all this data to guess failures. AI plans maintenance at the best time. You do not waste time or money on repairs you do not need. You keep your store running and your customers happy.

Tip: Use ai-based predictive maintenance to connect your sensors and data with smart AI algorithms. You will have fewer breakdowns and more uptime.

Key Technologies

Edge Computing

Edge computing lets you see what is happening right now. It works near your store machines, not far away. This means you do not wait long for data. Your store can react fast to what customers need. You can use edge computing for smart checkouts and store robots. It also helps with quick sales and catching fraud.

Edge computing handles data close by, so answers come fast.

You fix problems quickly, which helps your store run better.

Local data work means less waiting, which is good for sales.

Stores use edge computing to connect many systems. This helps your store work as one team. Many stores use edge tech to keep machines working and stop downtime. You need people who know how to run edge devices. Sometimes, network problems or high costs make it hard to use edge computing everywhere. You also need to keep customer data safe from hackers.

Challenge Type | Description |

|---|---|

Managing Edge Devices | You must control lots of devices in many stores. |

Need for Skilled Experts | You need people who know both IT and store systems. |

Network and Connectivity Issues | Bad networks can slow down how fast data moves. |

Compliance and Regulatory Hurdles | You must follow rules to keep data safe and avoid trouble. |

High Initial Investment | Buying new hardware and software costs a lot at first. |

Security and Data Privacy Concerns | You must protect customer data from hackers and leaks. |

Tip: Try a small edge computing project first. You can learn to handle devices and keep data safe before doing more.

AR/VR Tools

AR and VR tools help your team fix machines faster. You can use AR glasses to see inside machines and look at sensor data. This helps you find problems quickly. VR lets you practice fixing things before you do it for real. Mixed reality tools let you work with experts who are far away.

AR/VR Tool | Application | Benefit |

|---|---|---|

AR Overlays | Show sensor data | Helps you find problems fast |

VR Simulations | Practice fixing things | Makes you fix things quicker |

MR Tools | Work with experts online | Fixes take less time |

Many companies use AR glasses to make repairs faster. You can see inside machines and fix them with fewer mistakes. AR helps you find problems and keep repairs good. Some stores use AR to pick products, which makes work faster by up to 25%. You can use these tools to train your team and get better at fixing machines.

Note: AR and VR tools make fixing machines easier. You can solve problems faster and keep your store machines working longer.

Downtime Reduction

Early Detection

Predictive maintenance helps stop most surprise downtime in stores. Many problems in ai store machines happen because of broken parts, mistakes, supply issues, or missed checkups. When you use cheap sensors and live data, you spot trouble early. IoT sensors and monitors watch your machines all the time. You get alerts if something changes, like heat going up or odd shaking.

Finding problems early lets you plan repairs before things break. Your machines keep working and you avoid big breakdowns. Stores using predictive maintenance see big changes:

Benefit | Description |

|---|---|

Fixing things early stops surprise failures and keeps stores open. | |

Improved Operational Efficiency | Better repair plans make stores run smoother and use resources well. |

Cost Savings | Stops expensive emergency fixes and helps machines last longer. |

Enhanced Customer Satisfaction | Working machines mean better service and happier shoppers. |

You keep your store safe and protect your machines. Early fixes stop accidents before they happen. You also save money because you do not need to buy new machines. Stores say they have 70% fewer breakdowns and spend 25% less on repairs with predictive maintenance. Some stores save $500,000 on repairs and $230,000 each year on scrap for each line. Your machines keep running and customers stay happy.

Note: Predictive maintenance helps you catch big problems early. You keep your store safe and open for business.

Automated Maintenance Scheduling

Automated scheduling makes your store work better. You use smart data to plan repairs at the right time. AI tools help you watch your machines and make repair jobs. You do not have to guess when to fix things. The system tells you what needs fixing and when.

You get these good things from automated scheduling:

You can see where your machines are and how they are doing.

The system makes repair jobs for you, so you do less paperwork.

It helps you fix the most important problems first.

Repair plans fit your store’s needs and keep things running.

Siemens used predictive maintenance and cut repair costs by half. They also had 30% less downtime. Changing from fixing things after they break to fixing them before saves money and time. Stores also save $30,000 a year on parts for each place and stop five weeks of press downtime.

Improvement Type | Percentage/Amount |

|---|---|

Reduction in breakdowns | 70% |

Reduction in maintenance costs | 25% |

You get more done and your machines last longer. Automated scheduling helps you use your time and money better. You do not waste effort on repairs you do not need. Your machines are always ready for customers.

Tip: Use predictive maintenance and smart scheduling to make your store work better. You will have fewer breakdowns and more working time.

Maintenance Type | Description | Best Suited For |

|---|---|---|

Predictive Maintenance | Watches machines in real time and uses data to guess when they might break. | Important, expensive machines |

Preventive Maintenance | Plans regular repairs to stop surprise breakdowns. | Machines that wear out in a normal way |

Pick predictive maintenance for your most important machines. Use preventive maintenance for machines that wear out slowly. Both ways help your store, but predictive maintenance gives you more control and better results.

Implementation Steps

Getting Started

You can use predictive maintenance in your store by taking simple steps. First, check what you want to do and which machines need help. Look at your equipment and see which ones break the most. Then, put sensors on these machines and set up the right tools. Connect the sensors to your data system so you can watch your machines.

Decide what you want from predictive maintenance.

Put sensors on your machines and set up your system.

Bring all your machine data into one place.

Build and teach ai models with your data.

Try your system with a small test and get feedback.

Use predictive maintenance for all your machines in the store.

Watch your machines and make your process better over time.

You might have problems like bad data, mixing old and new machines, high costs, or workers not wanting to change. You need smart people to run the machines and handle different data. Keep your data safe and protect your systems from hackers.

Tip: Start with one group of machines before using predictive maintenance everywhere. This helps you learn and fix problems early.

Measuring Success

You can see if predictive maintenance works by checking important numbers. Use a main system to watch your machines and plan repairs. See how often machines break and how fast you fix them. Check how long machines sit unused and how well you use them.

Metric | Description |

|---|---|

Utilization Rates | Shows how well you use your equipment. |

Repair Intervals | Tracks how often you need repairs. |

Idle Times | Measures when machines are not working. |

Mean Time Between Failures (MTBF) should be 500 to 2,000 hours for most machines.

Mean Time to Repair (MTTR) tells you how fast you fix things.

Overall Equipment Effectiveness (OEE) over 85% means your store is doing great.

You can find ROI with this formula: ROI = (Total Benefits − Total Costs) ÷ Total Costs × 100. Benefits are less downtime, fewer emergency repairs, longer machine life, and better work. Costs are for sensors, software, and training. Most stores want to double their money in six to twelve months.

Note: Watch for downtime and why it happens. Use KPIs to show how predictive maintenance helps your store.

You get lots of good things when you use predictive maintenance in your store. This way helps you have less downtime and spend less on repairs. Your customers are happier because your machines work without breaking suddenly. In stores, predictive maintenance can lower costs by up to 25%. It also helps your store run better every day. Over time, your machines last longer, your store is safer, and things work faster. Look at how you fix things now and think about using predictive maintenance to help your store stay ahead.

FAQ

What is predictive maintenance?

Predictive maintenance means sensors and AI watch your machines. You get a warning before something breaks. This lets you fix things early. Your store keeps working without big stops.

How do sensors help with predictive maintenance?

Sensors check things like heat and shaking. They send this data to you. You can find small problems fast. Fixing them early stops bigger trouble and saves money.

Can predictive maintenance save money?

Yes! You pay less for emergency fixes. Your machines work longer. Many stores save up to 25% on costs.

Is predictive maintenance hard to set up?

You begin with a few sensors on key machines. Use easy software to watch the data. As you learn, you can add more sensors.

What skills do I need for predictive maintenance?

You need to know basic computer tasks. Your team should learn to use sensors and read the data. Training helps everyone do a better job.

See Also

The Future of Retail: Embracing AI-Driven Stores

Modern Retail Benefits from AI-Enhanced Combo Vending Machines

Transforming Online Store Management with AI E-Commerce Tools

Key Maintenance Tips for Vending Machine Security Features

Understanding AI-Driven Corner Stores: Insights for Retailers