How robotics and automation improve order picking in smart warehouses

Robotics and automation are changing order picking in smart warehouses. In Amazon’s fulfillment centers, more than 750,000 robots and advanced AI systems work with people. They help make operations 20% more efficient. DHL uses collaborative robots to get a 50% increase in productivity. These technologies make order fulfillment faster, safer, and more accurate. The table below shows how smart warehouses get better with these solutions:

Metric | Improvement/Impact |

|---|---|

Picking errors | |

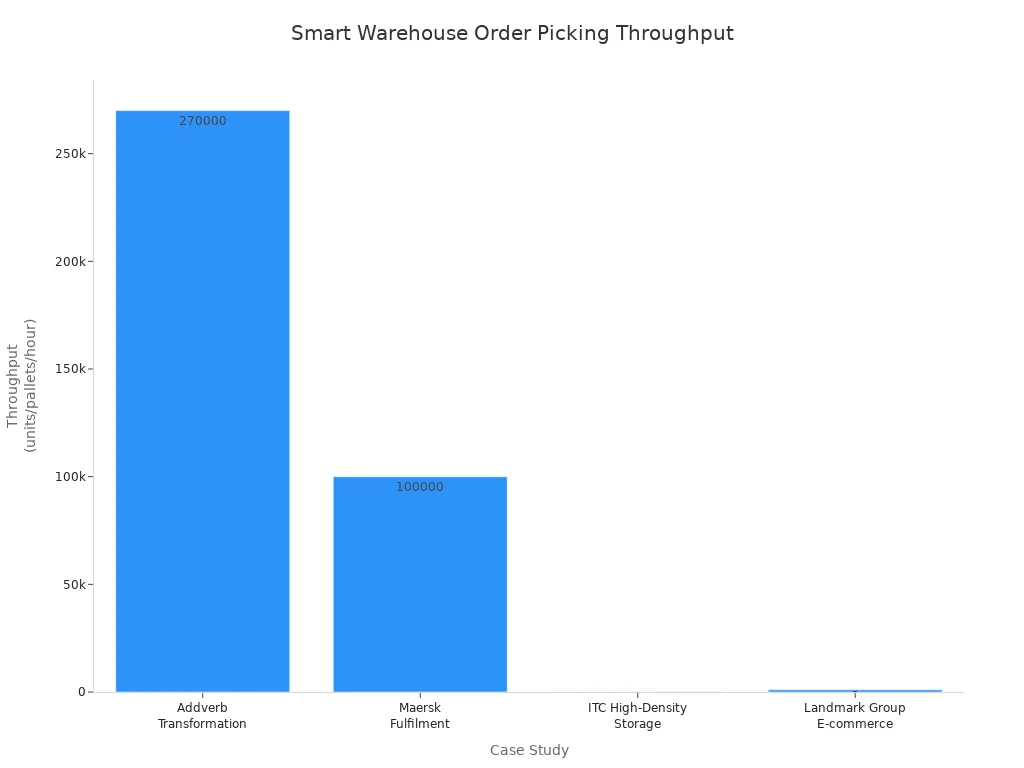

Throughput | Improved by 2-3x |

Inventory accuracy | Achieve 99% accuracy |

Order picking is very important for warehouse efficiency and customer happiness. Companies use automation to handle big demands and send orders fast.

Key Takeaways

Robotics and automation can make order picking faster by 50%. This helps warehouses fill many orders quickly.

Smart warehouses make fewer picking mistakes, up to 70% less. They also keep track of items with 99% accuracy. This makes customers happy.

Using things like autonomous mobile robots and goods-to-person systems saves time. It also helps warehouses spend less money to run.

Teaching workers about new technology is very important. It helps them learn new skills and keeps their jobs safe.

Order Picking in Smart Warehouses

What Is Order Picking?

Order picking means choosing items from shelves to fill orders. Workers or machines get products from a list. Smart warehouses use new ways to pick items faster and better. These ways are not like old picking methods. The table below explains how each method works:

Order Picking Method | Description |

|---|---|

Autonomous Order Systems | Use AI and automated pickers to get items from inventory and bring them to the right place. |

Pick-to-light | An automated system uses LED lights to show pickers the right items and amounts. |

Voice picking | Pickers get spoken instructions through headsets, so they can use both hands. |

Mobile Scanner-based Picking | Pickers use mobile scanners to see pick lists and check accuracy with real-time updates. |

Zone-Batch-Wave Picking | This method mixes different picking styles and uses set times to make picking more efficient. |

Collaborative Mobile Robots | These robots help people by moving products and finding the best routes with AI. |

Robotics and automation help smart warehouses improve these picking methods. Machines and systems help workers pick items faster and make fewer mistakes.

Why Order Picking Matters

Order picking costs more than any other warehouse job. It can be up to 63% of all costs. Fast and correct picking helps companies send the right products to customers. The table below shows why order picking is important:

Aspect | Evidence |

|---|---|

Cost Impact | Order picking can be up to 63% of warehouse costs, making it the most expensive job. |

Customer Satisfaction | Fast and correct picking helps customers get their orders on time and in good shape. |

Efficiency in E-commerce | How fast orders are picked affects how soon customers get their items, which matters a lot. |

If picking and packing is slow, it can take longer to send orders because products are not in the right place or shelves are messy. Walking around the warehouse can take up half the time spent picking. Using batch or zone picking helps cut down walking and makes picking faster.

Smart warehouses use robotics and automation to fix these problems. They help companies spend less, work faster, and keep customers happy.

Robotics and Automation Technologies for Order Picking

Smart warehouses use different robotics and automation. These tools help order picking go faster and make fewer mistakes. Workers and machines work together as a team. The main systems are pick-and-place robots, autonomous mobile robots (AMRs), automated guided vehicles (AGVs), and goods-to-person systems. Each technology has special things that help the warehouse work better.

Pick-and-Place Robots

Pick-and-place robots have robotic arms. They grab items and put them in the right spot. These robots work fast and never get tired. New pick-and-place robots use AI to learn better ways to pick and place. They can pick more than 200 items every hour. Their accuracy is above 99.9%. They place items with precision of ±0.1mm, so they almost never mess up. Safety features help keep workers from getting hurt.

Feature | Description |

|---|---|

AI Optimization | AI helps robots pick items better. |

Cycle Times | Robots pick over 200 items each hour. |

Placement Precision | Robots place items very accurately. |

Continuous Operation | Robots work long hours without stopping. |

Safety Improvements | Safety features help prevent injuries. |

Scalability | Systems can grow or shrink as needed. |

Flexibility | Robots can pick many types of products. |

System Integration | Easy to connect with other systems. |

Some pick-and-place robots use 3D vision and sensors. They see products and shelves clearly. They can pick items while moving, which saves time. Their small size lets them fit in tight spaces and work faster than older machines.

Metric | Description |

|---|---|

Makespan (M) | Time needed to finish picking tasks. |

Cumulative Path Cost | Total cost of robot movement during picking. |

Autonomous Mobile Robots (AMRs)

AMRs move around the warehouse using smart sensors and AI. They do not need fixed paths to travel. These robots carry items from one place to another. AMRs help with split-case and full-case order picking. They make order processing faster and need less human work. AMRs lower human mistakes and help keep inventory correct. They can lift heavy things and do the same job over and over. This helps keep workers safe. Their sensors help them avoid obstacles and collisions.

AMRs help warehouses work faster and safer. They automate material flows and make sure orders are picked and delivered on time.

Automated Guided Vehicles (AGVs)

AGVs use lasers, magnets, and cameras to find their way. They follow set routes in the warehouse. AGVs move goods between different areas. They help with stock replenishment and order picking. Their sensors and cameras watch for hazards. AGVs can stop if something is in the way. They work without human help and keep goods moving smoothly.

AGVs move products between storage and picking zones.

Collision warning systems help keep workers safe.

Vision technology helps AGVs move well in busy warehouses.

Goods-to-Person Systems

Goods-to-person systems bring products right to workers. Robots deliver items to a picking station. Workers do not need to walk around looking for products. This saves time and lowers mistakes. Algorithms help robots pick the right items and deliver them quickly.

Goods-to-person systems save time and cut down walking.

These systems lower mistakes and reduce customer returns.

Many smart warehouses use a mix of these technologies. Some use pick-to-light systems, voice picking, horizontal carousels, and vertical lift modules. These systems help guide workers and store products in less space. They also make picking faster. Collaborative robots, called cobots, work with people to do the same task many times. Palletizing robots help load and unload goods.

Technology | Main Function |

|---|---|

Robotics-Based Picking | |

Pick-to-Light Systems | Uses lights to guide workers to the right items. |

Voice Picking Systems | Gives voice commands to help workers pick items. |

ASRS | Stores and gets goods automatically. |

Horizontal Carousels | Rotates shelves for batch picking. |

Vertical Lift Modules | Uses vertical space for storage. |

AGVs | Moves goods along set paths. |

AMRs | Navigates freely with AI. |

Pick and Place Robots | Picks and places items with robotic arms. |

Goods-to-Person Robots | Brings items to workers. |

Collaborative Robots | Helps humans with repetitive tasks. |

Palletizing Robots | Loads and unloads pallets. |

Robotics and automation help warehouses use space better. They help workers do jobs faster and make fewer mistakes. When picking a system, companies look at their needs, safety features, and how easy it is to change or grow the system. Good support and training help keep these systems working well.

Benefits of Robotics and Automation

Speed and Productivity

Smart warehouses use robotics and automation to pick orders faster. Robots can make picking two or three times quicker than people. Automated systems finish orders in less than two minutes. This helps companies meet tight deadlines. AI-driven slotting puts products in the best places. This means pickers walk less. One case study showed order picking time dropped by 23% after using smart route planning.

Metric | Impact |

|---|---|

Order Cycle Time | |

Picking Productivity | Two or three times higher than manual picking |

On-Time Shipment Rate | Orders finished in less than two minutes |

Robots do boring jobs so workers can focus on important tasks. Working together makes everyone more productive.

Accuracy and Error Reduction

Robotics and automation help make picking more accurate. Automated systems can lower mistakes to less than 0.1%. Using robotics and RFID technology helps stop errors in order processing. These systems let warehouses handle busy times without hiring more people.

Metric | Improvement |

|---|---|

Picking Productivity | |

Order Accuracy | Mistakes cut to less than 0.1% |

Processing Speed | Orders finished in minutes |

Automated systems make picking faster and more accurate.

Warehouses can handle more orders during busy times.

Safety and Cost Savings

Robotics and automation make warehouses safer and save money. Robots lift heavy things and walk long distances. This lowers the chance of serious injuries. Automation can cut labor costs by up to 60%. It also boosts productivity by 30%. Fewer mistakes mean less money spent fixing errors.

Automation can cut errors by up to 99%.

The global warehouse robotics market may reach £31.3 billion by 2032.

Robots help lower severe injuries by doing risky jobs.

Factor | Description |

|---|---|

Labor Optimization | Less need for people, lower costs |

Energy Efficiency | Robots use less energy than old machines |

Maintenance Minimization | Smart diagnostics help control repair costs |

Inventory Management | Real-time tracking stops too much or too little stock |

Safety gets better, but new risks like loud noise and extra machine guards can happen. Companies must fix these problems to keep workers safe.

Implementation Challenges and Workforce Impact

Integration and Cost

Smart warehouses have problems when they add robotics and automation. New technology costs a lot of money. Companies pay for machines, setup, and fixing things. Connecting robots to old warehouse systems takes time and work. Many places must link new robots with old software. This is not easy.

Companies spend time and money to set up and test.

Data safety matters more as systems collect more info.

Workers may not like changes because they fear losing jobs.

Cost Element | Description |

|---|---|

Initial Investments | Buying and setting up automation systems. |

Ongoing Operational Costs | Fixing, teaching, and running systems every day. |

Factors Influencing Costs | Type of technology, warehouse size, brand, and plans to grow. |

Using both robots and skilled workers helps warehouses work better. This way, they do not need to build new buildings.

Workforce Adaptation

Robotics and automation change what warehouse workers do. Workers need new skills to use and fix machines. Training programs teach workers about robotics, AI, and data. These programs help workers feel sure and do their jobs well.

Workers need technical skills for new jobs.

Teamwork and leadership matter more as robots do simple jobs.

Learning all the time helps workers keep up with changes.

Key Training Areas | Description |

|---|---|

Operating Systems | Training to use and fix new systems. |

Safety Protocols | Learning how to stay safe around robots. |

Software Interfaces | Using software to track and manage inventory. |

Many workers worry about keeping their jobs. About 60% feel unsure about automation. Training and help can make workers less worried and help them learn.

Change Management

Handling change is important for automation to work. Companies watch how new systems do and use data to get better. They teach workers how to use new machines and software. Training often helps workers feel good about robots.

Look at current systems to find ways to improve.

Use key numbers to help make new plans.

Change picking steps for long-term success.

IT teams help make sure everything works together.

Working together and always improving helps warehouses do well with automation.

Robotics and automation help smart warehouses pick orders faster. They also help workers make fewer mistakes. These systems lower costs for companies. They make work safer for everyone. Companies can handle more orders when it gets busy. Warehouses using these tools see better order accuracy. They can grow and get bigger quickly. Experts think new trends will change the future:

AI will plan pick paths and manage resources all year.

Robots will do harder jobs, like inventory management.

Automation will help make workplaces safer and greener.

Technologies like AMRs and AS/RS will change warehouse work.

Warehouse managers who use these solutions get a big advantage. They are ready for new problems in the industry.

FAQ

What is the difference between AMRs and AGVs?

AMRs use sensors and AI to move around on their own. AGVs travel on fixed paths using magnets or lasers. AMRs can find new ways if something blocks them. AGVs always stay on their planned tracks.

How do robots improve safety in warehouses?

Robots pick up heavy things and do the same jobs many times. This helps stop injuries from lifting and moving stuff. Safety sensors make robots stop if people get too close. Workers are safer because robots do the risky work.

Can automation work with existing warehouse systems?

Most automation tools can connect to warehouse software already in use. Companies use special tools to link robots with other systems. Training helps workers learn how to use both old and new technology.

What skills do workers need in automated warehouses?

Workers learn how to use robots and computer programs. They follow safety steps and fix small issues. Training classes teach them new things. Workers get used to new technology as it changes.

How does automation affect order accuracy?

Automated systems use sensors and software to pick the right items. Robots follow steps and check products before sending them out. Mistakes go down to less than 0.1%. Customers get the correct orders more often.

See Also

Revolutionizing Online Store Management With AI E-Commerce Tools

Boosting Efficiency And Customer Experience With Cloudpick Checkout Systems

The Future of Retail Lies In AI-Powered Stores

Fast Food Automation: The Rise of Smart Vending Machines

Exploring Features And Advantages of AI Combo Vending Machines