Shopping Cart Materials

Shopping cart materials include carbon steel, stainless steel, plastic, and hybrid blends. These common materials used in shopping cart manufacturing shape the strength and weight of standard shopping carts. Shoppers see how shopping cart construction impacts durability and cost. The choice of shopping cart materials also plays a big role in sustainability. Environmental concerns and environmental regulations now influence which materials stores select for their carts.

Key Takeaways

Metal, plastic, and hybrid materials shape shopping carts’ strength, weight, and cost.

Metal carts last long and carry heavy loads but need regular maintenance to prevent rust.

Plastic carts resist rust, cost less, and work well in wet or coastal areas.

Hybrid carts combine metal and plastic for durability and easy handling with less upkeep.

Choosing recycled and lighter materials helps stores save money and protect the environment.

Common Materials Used

Metal

Many stores choose metal for their shopping carts. Metal carts use sturdy metals like carbon steel and stainless steel. These carts last a long time and can carry heavy loads. Stainless steel resists rust and keeps carts looking clean. Most supermarkets and large retailers prefer metal carts because they are strong and easy to sanitize.

Metal carts hold the largest market share in the retail industry.

Metal carts: 60% market share in 2023

Steel carts (a subtype): 10% market share and growing fast

Cart Type | Market Share (2023) | Notes |

|---|---|---|

Metal | 60% | Dominant market share |

Steel | 10% | Fastest-growing, durable, eco-friendly |

Plastic

Plastic carts have become more popular in recent years. These carts use durable plastics that make them lightweight and easy to move. Plastic carts do not rust, so they work well in wet or coastal areas. Many stores pick plastic carts because they cost less and are simple to clean.

Plastic carts: 30% market share in 2023

Demand for plastic carts rises due to cost-effectiveness and sustainability

Plastic carts now carry heavier loads because of new plastic technology. Many stores use plastic carts to lower costs and help the environment.

Hybrid

Hybrid shopping carts combine metal and plastic parts. These carts use metal frames for strength and plastic baskets for lighter weight. Hybrid carts offer a balance between the benefits of metal and plastic. Stores that want both durability and easy handling often choose hybrid carts.

Hybrid carts do not have a clear market share, but many retailers use them for flexibility.

The common materials used in shopping carts—metal, plastic, and hybrid—give stores many options. Each type fits different needs for strength, weight, and cost.

Shopping Cart Materials Comparison

Durability

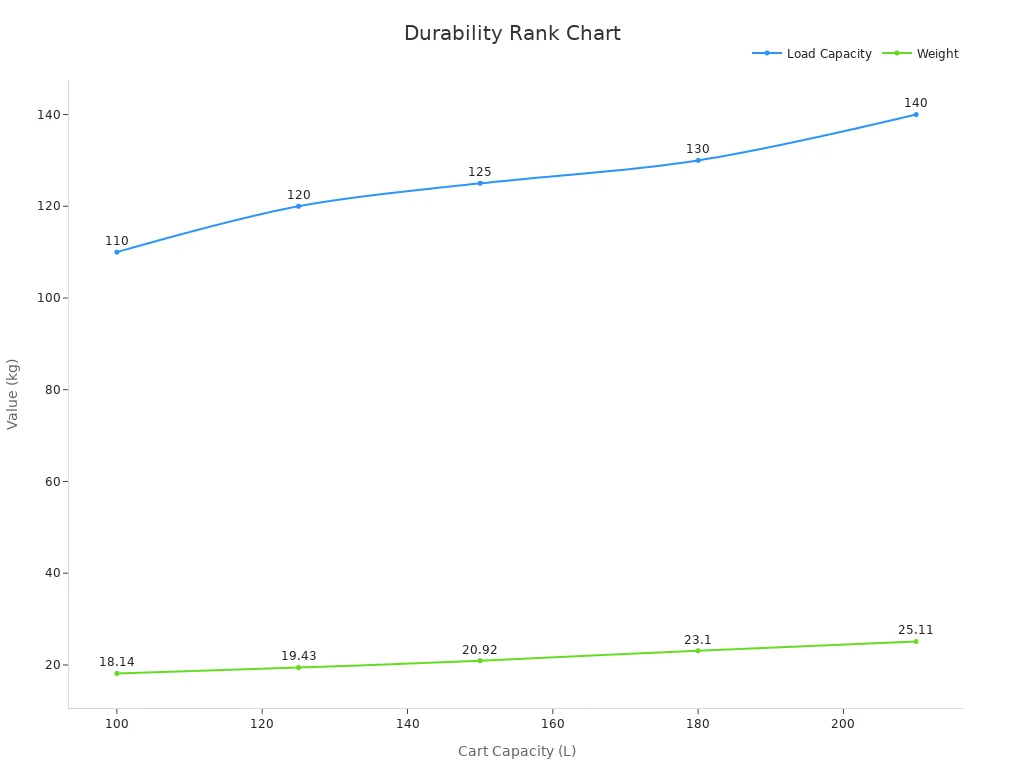

Durability measures how well a cart stands up to daily use. Metal carts show high strength and can carry heavy loads. Most metal carts last four to six years in supermarkets. Their load capacity ranges from 110 kg to 140 kg, and their weight increases with size. The table below shows how metal carts compare by size:

Weight (kg) | Load Capacity (kg) | Lifespan (years) | |

|---|---|---|---|

100 | 18.14 | 110 | 4 to 6 |

125 | 19.43 | 120 | 4 to 6 |

150 | 20.92 | 125 | 4 to 6 |

180 | 23.1 | 130 | 4 to 6 |

210 | 25.11 | 140 | 4 to 6 |

Plastic carts resist rust and dents but may crack under heavy impact. Hybrid carts, like the Ross model made from high-density polypropylene, combine metal frames with plastic baskets. These carts weigh about 15 kg and hold up to 180 liters. In tests, hybrid carts survived over 500 loading cycles and drops from 100mm to 450mm. They kept their structure and resisted wear better than metal or plastic alone. Hybrid carts also use rust-proof and dent-resistant materials, which increases their durability and lowers maintenance needs.

Hybrid carts now lead in durability, especially in busy stores. Metal carts still offer strong performance, but they need more care to prevent rust. Plastic carts work well in wet or coastal environments but may not last as long under heavy use.

Cost

Cost affects which shopping cart materials stores choose. Plastic carts usually cost less to buy, with prices from $40 to $150 for most models. High-end plastic carts can cost more. Wire or metal carts cost between $50 and $200, with premium models costing even more. Hybrid carts often fall in the mid to high price range because of their advanced shopping cart design.

Plastic Carts | Wire Carts | |

|---|---|---|

Initial Purchase Price | $40-$150 (low to mid-range), $150+ (high-end) | $50-$200 (low to mid-range), $200+ (high-end) |

Maintenance Costs | Generally lower short-term maintenance costs | Higher frequency of minor repairs |

Repair Considerations | May require complete replacement when damaged | Parts replaceable; repairs like welding possible |

Cleaning Costs | Lower due to easier sanitization | Higher due to complex structure |

Lifespan & ROI | Potentially shorter lifespan; quicker initial ROI | Longer lifespan with repairs; better long-term ROI |

Plastic carts save money at first and cost less to clean. Metal carts may cost more to repair, but stores can replace parts instead of the whole cart. Hybrid carts cost more up front but save money over time because they last longer and need fewer repairs.

Tip: If yearly repair costs reach half the cart’s original price, stores should consider replacing the cart.

Maintenance

Maintenance keeps carts safe and looking good. Metal carts need regular checks for rust and loose parts. Stores often repair metal carts by welding or replacing wheels and handles. Plastic carts need less care because they do not rust, but cracks or breaks mean the whole cart may need replacing. Hybrid carts use rust-proof materials and dent-resistant plastic, so they need the least maintenance.

Routine cleaning and monthly checks help all carts last longer. Wheels and handles often need the most attention. Repairing these parts costs between $20 and $50. Frequent repairs can add up, so stores look for carts with strong materials and simple shopping trolley design.

Best Uses

Each material fits different store needs and environments:

Metal carts work best in high-volume supermarkets. Their strength and quality make them ideal for heavy loads and frequent use.

Plastic carts suit stores in coastal or wet areas. They resist rust and weigh less, making them easy to move.

Hybrid carts fit stores that want both durability and easy handling. Their material selection gives them strength, quality, and long life.

Note: Hybrid carts perform well in busy stores and harsh environments. Their design resists rust and dents, making them a top choice for stores near the ocean or with high customer traffic.

Choosing the right shopping cart materials depends on store size, location, and budget. Good material selection improves quality, strength, and durability, helping stores serve customers better.

Heavy-Duty Shopping Carts

Protective Coatings

Heavy-duty shopping carts need strong protection to last in tough environments. Manufacturers use special coatings to keep these carts in good shape. Zinc plating covers the metal parts and stops rust from forming. Powder coating adds another layer that resists scratches and chips. These coatings help heavy-duty shopping carts stay clean and safe for customers. Some stores choose carts with antimicrobial coatings. These coatings fight germs and make the carts safer for everyone. Protective coatings also help carts keep their color and shine. Heavy-duty shopping carts with good coatings show better performance in wet or salty air. Stores in coastal areas often pick these carts because they last longer.

Tip: Regular cleaning helps protective coatings work better and keeps heavy-duty shopping carts looking new.

Outdoor and Indoor Use

Stores use heavy-duty shopping carts both inside and outside. These carts work well in parking lots, garden centers, and large retail spaces. Heavy-duty shopping carts have strong frames and large wheels. These features help them move smoothly over rough ground. The carts can carry heavy items without bending or breaking. Their load-bearing capability makes them a top choice for stores with big products. Heavy-duty shopping carts resist damage from sun, rain, and snow. This resistance comes from their tough materials and protective coatings. Indoor use also benefits from these features. Heavy-duty shopping carts handle frequent use and heavy loads in busy supermarkets. Their design supports both safety and quality for shoppers.

Heavy-duty shopping carts:

Last longer in harsh weather

Carry more weight than standard carts

Need less repair over time

Work well in both indoor and outdoor settings

Heavy-duty shopping carts give stores a reliable option for many uses. Their strong build and special coatings help them stand up to daily challenges.

Wheels and Handles

Wheel Materials

Wheel materials play a key role in how a shopping cart moves and performs. Stores select wheels based on the surfaces their carts will travel over and the loads they must carry. Each material offers unique benefits and drawbacks.

Rubber wheels provide a quiet ride and smooth movement. They grip indoor floors well and reduce noise in busy aisles. However, they wear down quickly on rough outdoor surfaces.

Polyurethane wheels last longer than rubber and resist chemicals and abrasion. These wheels work well both indoors and outdoors. They cost more but offer a quieter ride than metal wheels.

Plastic wheels are lightweight and resist corrosion. They move easily on smooth floors but may crack under heavy loads or rough use.

Metal wheels handle heavy loads and last a long time. They suit industrial settings but can be noisy and may damage indoor floors.

The table below compares wheel materials and their best uses:

Material | Key Features | Suitable Environments |

|---|---|---|

Metal | High load capacity, heat tolerant | Industrial, heavy loads |

Rubber | Good traction, shock absorbing, quiet | Indoor, outdoor, medium-duty |

Polyurethane | Durable, floor protection, quiet | Retail, warehousing, smooth floors |

Nylon/Plastic | Lightweight, chemical resistant | Food processing, cleanrooms, warehouses |

Pneumatic/Solid | Handles rough, uneven surfaces | Outdoor, rough terrain |

A well-chosen wheel material improves shopping cart design by making carts easier to push and safer for customers.

Handle Materials

Handle materials affect comfort, hygiene, and durability. Most shopping trolley design uses plastic or rubber-coated handles. These materials feel comfortable and prevent slipping. Some carts use metal handles for extra strength, but these can feel cold or slippery. Stores often choose plastic handles because they resist germs and clean easily. Rubber grips add comfort and help shoppers keep control, especially when hands are wet. High-end carts may feature antimicrobial coatings on handles to reduce the spread of germs. Handle design and material choice help stores create a safe and pleasant shopping experience.

Tip: Stores should check handles regularly for cracks or wear to keep carts safe and comfortable for everyone.

Sustainability

Recycled Materials

Retailers now focus on sustainability when choosing shopping cart materials. Many manufacturers use recycled materials to reduce waste and lower costs. Statistics from the Environmental Protection Agency show a 28% increase in the use of recycled materials in retail equipment, including shopping carts. In 2023, eco-friendly shopping cart materials grew by 12% year-over-year. These numbers show a clear trend toward more sustainable choices.

Rising prices for new plastics, such as a 36% increase in polypropylene since 2020, push companies to seek recycled plastics. Recycling centers now supply more materials for shopping carts. This shift helps stores save money and supports environmental sustainability. Recycling methods also improve, making it easier to reuse plastics and metals in new carts.

Using recycled materials in shopping carts helps protect the environment and supports a circular economy.

Environmental Impact

Environmental impact assessments compare the sustainability of metal, plastic, and hybrid shopping cart materials. These studies look at greenhouse gas emissions, energy use, and waste. Key findings include:

Plastic shopping carts often have lower greenhouse gas emissions than metal carts because they need less energy to produce and transport.

Metal carts, especially steel, last longer and can be recycled many times, which improves their environmental profile.

Hybrid carts combine the benefits of both materials, offering durability and lower weight, which can reduce transport emissions.

Lighter carts, such as those made from plastic or hybrid materials, help stores save fuel during shipping and reduce their overall environmental footprint.

The table below summarizes the environmental features of each material:

Material | Greenhouse Gas Emissions | Durability | Recyclability | Weight |

|---|---|---|---|---|

Metal | Higher | High | High | Heavy |

Plastic | Lower | Medium | Medium | Light |

Hybrid | Medium | High | Medium | Light |

Stores that choose carts made from recycled materials and lighter components help reduce their impact on the environment. These choices support sustainability and meet growing customer demand for eco-friendly products.

Shopping cart materials differ in strength, weight, and cost. Metal carts offer high durability for busy stores. Plastic carts resist rust and work well in wet areas. Hybrid carts balance strength and easy handling. Store owners should consider store type, location, and budget before choosing. Sustainability matters for stores that want to reduce their environmental impact. For more details, readers can explore guides on cart maintenance and eco-friendly retail solutions.

FAQ

What material lasts the longest in shopping carts?

Stainless steel usually lasts the longest. It resists rust and damage. Stores that use stainless steel carts often see them last for many years. Hybrid carts also show strong durability because they combine tough metal frames with sturdy plastic parts.

Are plastic shopping carts safe for heavy loads?

Plastic carts can carry heavy groceries, but they have weight limits. Most plastic carts hold up to 120 kilograms. Stores should check the manufacturer’s guidelines before loading. For very heavy items, metal or hybrid carts work better.

How do stores clean shopping cart materials?

Stores clean carts with mild soap and water. They use disinfectant sprays for handles and baskets. Plastic and stainless steel surfaces clean easily. Regular cleaning keeps carts safe for shoppers and helps prevent the spread of germs.

Do shopping cart materials affect the environment?

Yes, shopping cart materials impact the environment. Metal carts use more energy to make but can be recycled many times. Plastic carts use less energy but may not recycle as easily. Hybrid carts balance both features. Many stores now choose recycled materials.

Which shopping cart material works best near the ocean?

Plastic and hybrid carts work best near the ocean. They resist rust from salty air. Stainless steel also performs well in coastal areas. Stores in these locations often avoid regular steel carts because they rust quickly.

See Also

Essential Fundamentals Of Corner Stores And Their Importance

The Impact Of AI Tools On Managing Online Stores

Helpful Self-Checkout Advice For Hassle-Free Garlic Purchases