Vending Machine Route Efficiency to Maximize Profit and Minimize Costs

Imagine you manage a vending machine business and spend hours each week driving between locations. You notice that some machines stay full while others run empty, hurting your profit and raising your costs. Industry studies show that improving route efficiency in the vending machine industry can boost profitability by up to 6% for popular machines. Smart planning, data analysis, and technology help you cut cost, reduce wasted trips, and increase vending sales. When you focus on efficient vending machine route management, you see higher profitability and lower costs across your vending operation.

Key Takeaways

Plan vending machine routes carefully to save time, cut costs, and keep machines stocked, which boosts profits and customer satisfaction.

Use real-time data and smart software to track inventory, optimize routes, and prevent empty or overstocked machines.

Choose vending locations and products based on customer needs and traffic patterns to increase sales and profitability.

Regular maintenance and quick repairs reduce downtime, protect revenue, and keep machines running smoothly.

Cut labor and travel costs by using route optimization tools, energy-efficient machines, and teamwork with other operators.

Route Efficiency

Why Route Efficiency Matters

You want your vending machine business to run smoothly and make more money. Route efficiency helps you reach this goal. When you plan your vending machine route well, you save time, cut costs, and keep your machines stocked. This means you spend less on fuel and labor, and your customers find what they want every time they visit.

Many factors influence route efficiency in vending. You need to think about where your machines are. High-traffic spots like malls, airports, and gyms bring in more sales. For example, protein bars sell three times more in gyms than in libraries. You also need to match your products to the people who use each location. Healthy snacks work better in fitness centers, while sodas might sell more in schools.

Here are some key factors that affect route efficiency in your vending machine business:

Location: Busy places increase sales and reduce wasted trips.

Consumer Preferences: Products that fit the location boost sales.

Operational Costs: Shorter travel between machines saves money.

Volume vs. Margin: Some routes have high sales but low profit per item, while others are the opposite.

Seasonality and Trends: Changing products with the season keeps sales high.

Competition: Other food options nearby can lower your sales.

Technology Integration: Cashless payments and remote tracking make your job easier.

Regulatory Compliance: Following local rules keeps your business safe.

Customer Service: Fast restocking and repairs keep customers happy.

When you improve route efficiency, you see real results. Studies show that better route planning can cut service time by up to 50%. This means you spend less on labor and fuel. On average, you can earn over $1,600 more per month for each machine. Using data analytics, AI-driven planning, and real-time inventory tracking helps you keep machines full and working. These tools let you adjust your schedule, prepare products before you leave, and serve more stops in one trip. Your vending machine business becomes more cost effective and reliable.

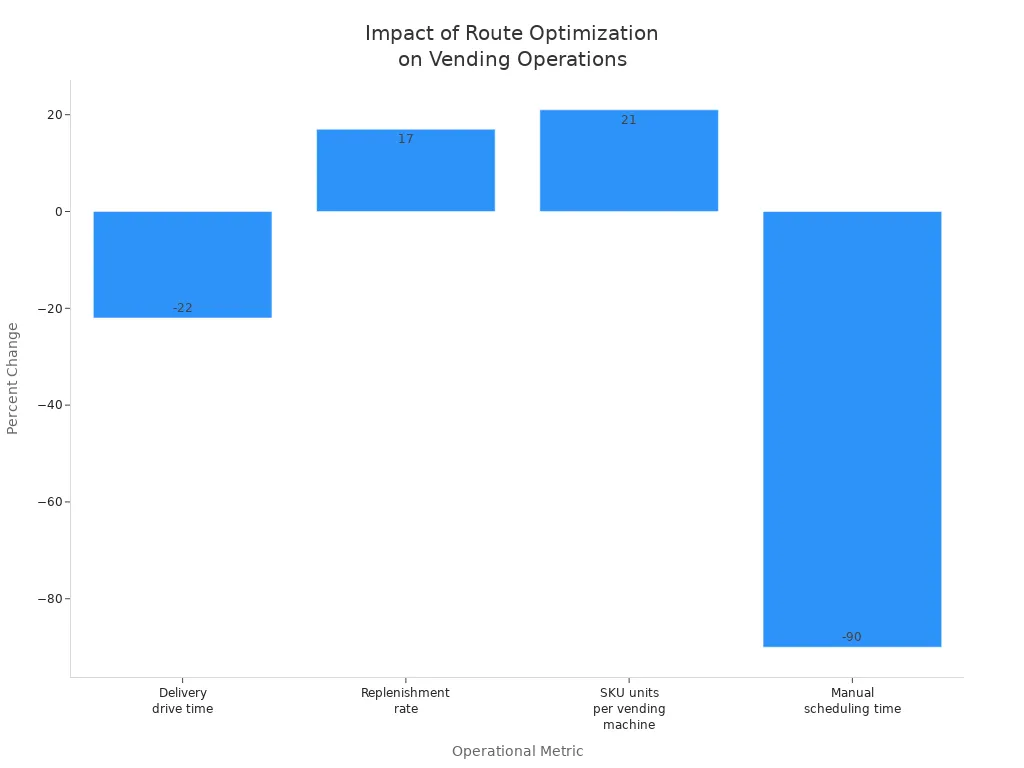

The impact of route efficiency is clear in real-world numbers. Take a look at how optimizing vending machine routes can change your business:

Metric | Improvement | Operational Cost Impact |

|---|---|---|

Delivery drive time | Reduces fuel and labor costs by shortening routes | |

Replenishment rate | 17% increase | Enhances inventory turnover, reducing stockouts and waste |

SKU units per vending machine | 21% increase | Increases sales potential per machine, improving revenue |

Manual scheduling time | 90% reduction | Cuts labor costs by automating route planning |

You can see that route efficiency leads to higher sales, lower costs, and better use of your time. Using data analytics and smart planning, you can turn your vending machine business into a more profitable and efficient operation.

Common Inefficiencies

Many vending machine businesses struggle with common problems that hurt route efficiency. If you do not manage your vending machine route well, you may face empty machines, wasted trips, and unhappy customers. These issues raise your costs and lower your profits.

Some of the most frequent inefficiencies include:

Poor inventory management, which causes empty or overstocked machines and reduces sales.

Maintenance problems that lead to machine downtime and lost revenue.

Payment system failures, making it hard for customers to buy products.

Product delivery issues, which affect stock availability.

Temperature control problems in refrigerated machines, leading to spoiled products.

Inadequate maintenance, causing more breakdowns and service calls.

Weak customer support, making it hard to fix problems quickly.

Not using technology like vending management software or remote monitoring tools.

Financial planning challenges, such as high startup costs and ongoing expenses.

Bad location strategy, which makes routes longer and less profitable.

When you ignore these inefficiencies, your vending machine business suffers. Inefficient route planning leads to stock shortages and extra trips. This increases your costs and causes delays in restocking and repairs. Machines stay empty or broken, which frustrates your customers and lowers satisfaction.

Professional route management, with real-time monitoring and data analytics, helps you avoid these problems. You can plan a more efficient route, reduce travel time, and keep your machines full and working. Regular maintenance and quick repairs also keep your machines running longer and make your customers happy. Using vending management software lets you calculate the best route and manage stock better. Drivers can restock and fix machines faster, which means more sales and better service.

By focusing on route efficiency and using the right tools, you can improve operational efficiency, save money, and grow your vending machine business.

Inventory Optimization

Preventing Stockouts

You want your vending machines to stay full and ready for customers. Stockouts can hurt your sales and make customers less likely to return. Good inventory management helps you avoid these problems. When you use real-time monitoring, you know exactly when to restock each machine. Sensors and inventory management software send alerts when products run low. This reduces the chance of empty shelves.

Here are some effective ways to prevent stockouts:

Analyze sales data to forecast demand and adjust stock levels.

Keep safety stock as a buffer for unexpected spikes in sales.

Use vendor managed inventory programs so suppliers help keep machines stocked.

Build strong relationships with suppliers for timely deliveries.

Monitor inventory in real time and set up automated alerts.

Improve your inventory management by checking data and updating your process often.

Tip: High machine uptime and fast inventory turnover keep customers happy and boost your revenue. When you prevent stockouts, you improve customer satisfaction and increase repeat business.

Avoiding Overstock

Overstocking ties up your money and can lead to expired products. You want to keep just enough stock to meet demand without wasting resources. Smart inventory management helps you find the right balance.

Try these strategies to avoid overstock:

Track key performance indicators like inventory turnover and customer availability rate.

Use ABC analysis to focus on top-selling products and reduce slow movers.

Remove slow or obsolete stock by running promotions or returning items.

Accept occasional shortages for items that do not sell well.

Forecast demand using sales data and adjust orders as needed.

Apply stock rotation methods, such as FIFO, to keep products fresh.

Negotiate lower minimum order quantities with suppliers to avoid excess stock.

Overstocking can hurt your profits. It locks up cash and increases the risk of waste. By using inventory management tools and data, you can keep your machines stocked with the right products and reduce losses.

Route Optimization Tools

Software Solutions

You can make your vending business more efficient by using the right software. Many vending solutions offer route optimization features that help you plan the best path for your drivers. These tools use data analytics to find the shortest routes and reduce wasted trips. You save money on fuel and spend less time on the road. The right vending management system can also help you track inventory and sales, making your job easier.

Here is a table of popular software solutions for vending machine route optimization:

Software Solution | Route Optimization Feature | Target User Base / Notes |

|---|---|---|

VendSoft | Yes | AI-powered planning; saves 30% on fuel; best for small to mid-sized operators |

Cantaloupe Systems | Yes | Enterprise analytics and routing; great for large fleets |

Nayax | No | Focuses on payments and telemetry |

Parlevel Systems | Yes | Smart routing and warehouse syncing for medium to large operations |

USATech VMS | Yes | Designed for regulated environments like schools |

VendSoft stands out for small to mid-sized operators. It uses AI to plan routes and pre-kit inventory, so drivers only carry what they need. This vending management system can cut fuel costs by up to 30%. Cantaloupe Systems and Parlevel Systems work well for larger businesses that need advanced analytics and smart routing.

Tip: Smart routing lets you serve more machines in less time, which means higher profits and lower costs.

Real-Time Monitoring

Real-time monitoring is a key part of modern vending solutions. With a vending management system, you get instant alerts when a machine runs low or has a problem. This real-time data helps you avoid unnecessary trips and keeps your machines full. You can group machines by location, prioritize high-performing stops, and adjust your schedule quickly.

Real-time monitoring gives you:

Immediate alerts for low stock or malfunctions

Data analytics to spot trends and plan better routes

Faster response to problems, which keeps customers happy

Dynamic route optimization based on current needs

Real-time data integration lets you track inventory, machine health, and sales as they happen. You can use this information to make quick decisions and keep your vending solutions running smoothly. With better data analytics, you improve service accuracy and reduce downtime. Your business becomes more reliable and profitable.

Dynamic Routing

Dynamic routing helps you make your vending machine business more efficient. You use real-time data to decide which machines need service and when. This approach saves time, reduces costs, and keeps your machines stocked. Two important strategies for dynamic routing are pre-kitting and adaptive scheduling.

Pre-Kitting

Pre-kitting means you prepare product totes for each vending machine before you leave your warehouse. You use real-time inventory data from your Vending Management System (VMS) to know exactly what each machine needs. This process makes dynamic routing much more effective.

Aspect | Explanation | Impact on Dynamic Routing Efficiency |

|---|---|---|

Definition of Pre-kitting | Preparing product totes for each machine using real-time inventory data | Eliminates multiple trips, reducing trips from three to one per machine |

Role of VMS | Monitors inventory and provides detailed product lists | Ensures correct delivery, reduces guesswork and spoilage |

Efficiency Gains | Allows route consolidation, reduces routes and drivers needed | |

Dynamic Routing | Uses real-time data to select only machines that need servicing | Saves time, reduces unnecessary stops, lowers operational costs |

Overall Benefits | Reduced labor, fewer routes, less spoilage, increased profitability | Enhances labor efficiency and cost savings |

Your VMS supports pre-kitting by giving you up-to-date sales and inventory information. You can see route progress and picking status on any device. As drivers finish their stops, the system updates automatically. This technology removes the need for third-party pre-kitting providers. You gain speed and accuracy, which makes dynamic routing even more powerful.

Adaptive Scheduling

Adaptive scheduling lets you adjust your service routes in real time. You use dynamic routing to respond quickly to changes and emergencies. This method improves flexibility and reduces downtime.

AI-driven scheduling assigns technicians based on availability, skill, and location. You get faster response times and less downtime.

Mobile apps send instant updates about job changes and route adjustments. Your team adapts quickly and avoids miscommunication.

Clustered appointments group service visits by area. You cut travel time and fuel costs, making your operation more efficient.

Dynamic routing with adaptive scheduling helps you serve more machines with fewer resources. You keep your machines running, your customers happy, and your costs low. When you use dynamic routing, you make your vending business smarter and more reliable.

Maximize Profit Strategies

High-Performing Locations

You want your vending machine business to reach its full potential. The right location can make a huge difference in your profitability. Many people think that high foot traffic always leads to more profit, but that is not always true. You need to look deeper and use a smart strategy for vending machine placement.

High-performing locations match your target audience. For example, you place machines near office breakrooms for employees or in hospital waiting areas for visitors.

Visibility matters. Machines near entrances or busy hallways attract more attention and sales.

Product relevance is key. You stock items that fit the needs and habits of people at each location.

Less competition nearby means higher profits. If your machine is the only option, you sell more.

Quality of the spot often beats the number of people passing by. A well-placed machine in a smaller but targeted area can outperform one in a crowded but less relevant space.

You need to understand what your customers want, when they buy, and how they shop. This helps you increase profits and maximize profit.

Use data analytics to study traffic patterns, customer demographics, and competition. This helps you choose the best spots for your machines.

Do not believe the myth that all locations are equally profitable. Strategic placement based on real insights leads to higher profitability and better results for your vending machine business.

Tip: Focus on quality, not just quantity, when choosing locations. The right spot with the right products will boost your profit and help you increase profits over time.

Product Selection

The products you choose for your vending machines have a big impact on profitability. You need to match your product selection to the people who use each machine. This strategy helps you increase profits and keep your vending machine business growing.

Strategy | Impact | Example/Effect |

|---|---|---|

Balanced mix of healthy & indulgent options | Increases customer base and sales volume | |

High-quality organic products | Improves profit margins | Margin improvements up to 20% |

Seasonal product rotation | Boosts revenue during peak seasons | Revenue increase of 12% |

You can use data analytics and IoT technology to track what sells best at each location. This lets you adjust your product mix in real time. You reduce spoilage and avoid stockouts, which increases your profit and keeps your machines running smoothly. Tailoring your product selection to each audience—like healthy snacks near gyms or quick meals in offices—helps you maximize profitability.

Understand your audience. Study the demographics at each location to pick the right products.

Rotate products for the season. Offer cold drinks in summer and hot beverages in winter to boost revenue.

Combine best-sellers with unique items. This attracts more customers and increases profits.

Offer different price points. You reach more people by having both budget and premium options.

Use a smart pricing strategy. Adjust pricing based on demand, location, and competition to improve profitability.

Monitor sales data often. Make changes quickly to keep your vending machines profitable.

Note: A strong pricing strategy and careful product selection work together to increase profits and drive profitability in your vending machine business.

You need to review your pricing and product mix regularly. This helps you stay ahead of trends and keep your vending machines profitable. When you use data analytics and focus on strategic vending machine placement, you set your business up for long-term success.

Cost Reduction

Labor and Travel Savings

You can lower the cost to service your vending machines by making smart choices about labor and travel. Many vending operators waste money on extra trips and long routes. You can avoid these problems by using a few proven methods:

Use vending machine dollies, utility carts, and protective packaging to make loading and unloading faster. This reduces the cost to service each stop.

Plan your routes with route optimization software. This tool helps you find the shortest path, cutting down on travel time and fuel costs.

Try Just-in-Time (JIT) delivery. You only restock when needed, which lowers the cost to service and keeps inventory lean.

Set delivery schedules based on demand. Look at peak hours and special events so you do not make unnecessary trips. This approach reduces operational costs and the cost to service each machine.

Use remote monitoring and data analytics. These tools let you track stock levels and machine status from your phone or computer. You only visit machines that need service, which saves on labor and travel costs.

Work with other vending operators to share delivery routes. This teamwork can lower the cost to service and split transportation costs.

Keep up with regular maintenance. Well-maintained machines break down less, so you avoid extra trips and reduce the cost to service.

Invest in vehicles and modular storage that fit your inventory size. This makes loading and unloading easier, saving time and reducing the cost to service.

These steps help you cut costs, improve efficiency, and keep your vending business running smoothly.

Energy Efficiency

You can also lower the cost to service your vending machines by choosing energy-efficient models. Traditional vending machines use a lot of electricity—between 2,500 and 4,400 kWh each year. This can cost you $300 to $700 per machine, depending on local rates. Energy-efficient vending machines use features like LED lighting, motion sensors, and high-efficiency compressors. These upgrades can reduce electricity use by up to 25%. ENERGY STAR-certified vending machines are about 40% more efficient than standard models. When you switch to these machines, you can cut your annual electricity costs by 25% to 40%. This big drop in operational costs means you spend less on every machine, lowering the total cost to service your entire vending route.

Tip: Upgrading to energy-efficient vending machines not only saves money but also helps the environment.

Maintenance and Uptime

Scheduled Maintenance

You keep your vending machines running smoothly when you follow a clear maintenance schedule. Regular care helps you avoid costly breakdowns and keeps your machines earning money. You should divide your maintenance tasks into daily, weekly, monthly, quarterly, and annual intervals. This approach helps you catch small problems before they become big ones.

Daily: Clean high-touch areas like keypads and coin slots. Spot-check for spills and residue to keep machines hygienic.

Weekly: Wipe down exterior surfaces and inspect internal parts. Empty trash and collection trays to prevent odors.

Monthly: Check mechanical parts and payment systems. Rotate inventory to avoid expired products and malfunctions.

Quarterly: Deep clean both inside and outside. Update software and review all mechanical systems.

Annually: Perform a full overhaul. Replace worn parts and update software to ensure long-term reliability.

Tip: Preventive maintenance is not just about cleaning. It protects your profits, extends machine life, and keeps customers happy.

When you stick to this schedule, you reduce the risk of unexpected repairs. You also meet safety and health regulations, which builds trust with your customers.

Downtime Prevention

You want your vending machines to work all the time. Downtime means lost sales and unhappy customers. Proactive maintenance helps you spot issues before they cause problems.

Inspect wiring and connectors often. Early detection of damage or corrosion prevents electrical failures.

Check mechanical parts like dispensing arms and refrigeration units. This avoids jams and keeps products fresh.

Schedule professional checks for motors, sensors, and cooling systems. These steps catch wear and tear before breakdowns happen.

Use remote monitoring tools. Real-time alerts help you fix problems like coin jams or compressor failures quickly.

Keep spare parts on hand. Fast repairs mean your machines spend less time out of service.

Regular inspections and quick responses help you reach near 100% uptime. You keep your machines reliable, protect your revenue, and make sure customers always find what they need.

Supplier Management

Bulk Purchasing

You can save money and boost your profits by buying your vending machine inventory in bulk. When you purchase large quantities, suppliers often give you volume discounts. These discounts lower your cost per item, which means you spend less on each snack or drink you sell. For many vending operators, bulk buying can improve profit margins by $250 to $1,000. Since inventory costs make up a big part of your expenses, even small savings add up fast.

Bulk purchasing also gives you more power when you negotiate with suppliers. You can ask for better prices, free delivery, or extra perks. Here are some tips to help you get the best deals:

Research your suppliers and know what other options you have.

Control the timing and setting of your negotiations to stay in charge.

Use your knowledge of the market and your supplier’s limits to push for better terms.

Stay confident and clear about what you want.

Tip: Always define your needs, such as machine type and product selection, before you start negotiations. This helps you avoid confusion and get the right products for your business.

Reliable Supply Chains

A strong supply chain keeps your vending machines stocked and your customers happy. You need to organize your inventory and plan ahead to avoid running out of products or having too much spoilage. Good supply chain management helps you avoid costly mistakes and keeps your business running smoothly.

Follow these steps to build a reliable supply chain:

Store products off the ground to keep them clean and safe.

Organize items by type and brand using shelves and bins.

Watch expiry dates and use the FIFO (first in, first out) method to sell older stock first.

Use inventory software or manual tracking to monitor levels and reorder points.

Project your needs based on sales trends and supplier delivery times.

Protect sensitive items, like chocolate, from heat with refrigeration.

Note: Regularly review your agreements and communicate with your suppliers. This helps you adapt to changes and maintain a steady flow of inventory.

A reliable supply chain and smart bulk purchasing work together to lower your costs and increase your profits. When you manage your suppliers well, you set your vending business up for long-term success.

Quick Tips

Immediate Actions

You can boost your vending machine route efficiency right away by making a few smart changes. Start by using advanced inventory management and warehouse picking software, such as Lightspeed Automation's Level and FastTrack systems. These tools help you track inventory, suggest the right purchase quantities, and guide your team through efficient picking routes. You save time on ordering, improve stock accuracy, and streamline pre-kitting. Many operators see inventory levels drop by 15-20% and labor hours decrease, which means lower costs and faster service.

Here are some steps you can take today:

Minimize unnecessary visits to machines. Only service machines that need attention.

Dedicate machines to specific product groups, like snacks or drinks, to reduce refill frequency.

Choose products with good shelf life and high sales velocity to keep inventory moving.

Move low-revenue machines closer to other accounts to cut travel time.

Adjust service intervals to prevent stockouts but avoid over-servicing.

Limit the number of product options in each machine to simplify restocking.

Keep machines fully stocked to maintain sales and keep your accounts.

Tip: Small changes in your daily routine can lead to big savings in time and money.

Long-Term Planning

For lasting success, you need a plan that keeps your vending business efficient as it grows. Group your machines by location to make routes shorter and easier to manage. Use route optimization software to cut travel time and lower costs. Schedule restocking based on real sales data, not just a fixed calendar.

Cluster machines in the same area to save on travel.

Analyze sales and foot traffic to pick the best locations, like offices, schools, or hospitals.

Use vending management software to automate inventory tracking and route planning.

Rotate products based on local preferences, seasons, and trends.

Set up preventive maintenance schedules to keep machines running and avoid costly repairs.

Build strong relationships with location owners and respond quickly to their needs.

Reinvest profits in technology and staff training to support growth.

Outstanding customer service and smart planning help you keep your machines profitable and your business growing.

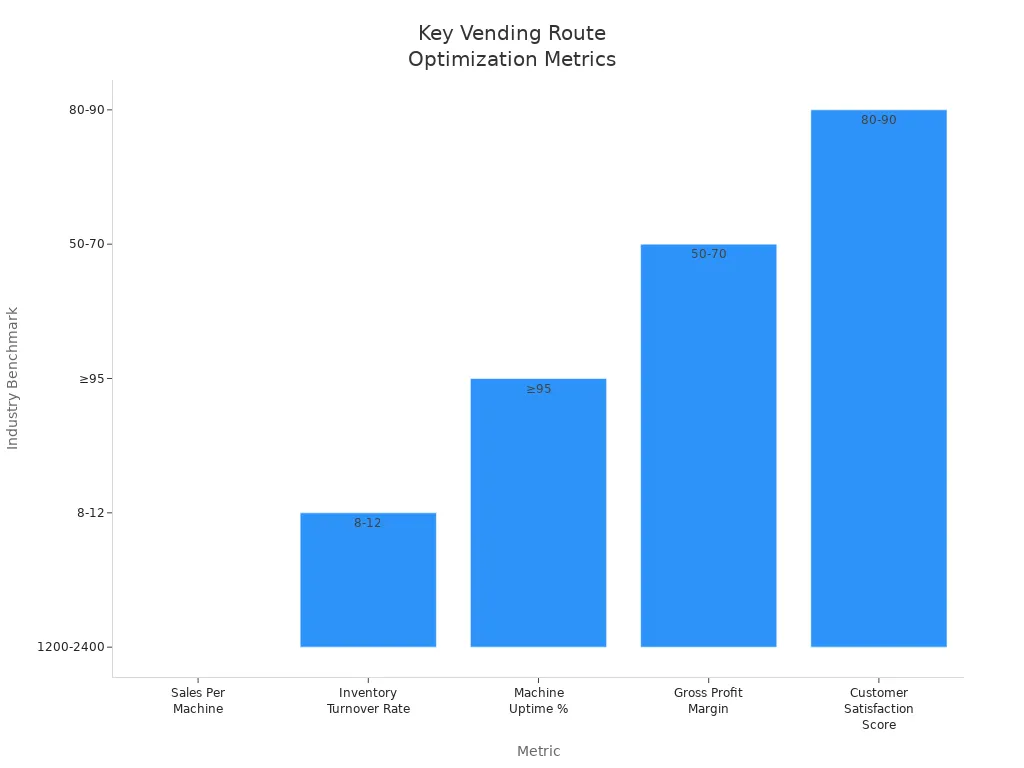

You can boost your vending business by focusing on route efficiency, smart inventory management, and regular maintenance. Track important metrics like sales per machine, inventory turnover, machine uptime, gross profit margin, and customer satisfaction to see real progress. The table below shows how each metric helps you lower cost and improve results:

Metric | Why It Matters |

|---|---|

Sales Per Machine | Shows top locations and profit |

Inventory Turnover Rate | Helps manage stock and reduce cost |

Machine Uptime % | Keeps machines working and cuts cost |

Gross Profit Margin | Measures how much profit you keep |

Customer Satisfaction | Brings repeat business and more sales |

Try one new tactic today and watch your cost drop. Keep tracking your results and adjust your routes for even better efficiency. Take charge of your vending operation and build a business that grows stronger every day.

FAQ

How often should you service your vending machines?

You should check your machines at least once a week. High-traffic locations may need more frequent visits. Use real-time monitoring to know when each machine needs attention.

What is the best way to choose products for each location?

Study your sales data and customer preferences. Pick products that match the needs of people at each site. Rotate items based on season and trends for better sales.

Can route optimization software really save you money?

Yes! Route optimization software helps you plan the shortest and fastest routes. You save on fuel, reduce labor hours, and avoid unnecessary trips. Many operators see lower costs and higher profits.

How do you prevent vending machine downtime?

Schedule regular maintenance and use remote monitoring tools. Fix small issues before they become big problems. Keep spare parts ready for quick repairs. This keeps your machines running and customers happy.

What should you look for in a vending management system?

Real-time inventory tracking

Route planning features

Sales and performance reports

Easy-to-use dashboard

Pick a system that fits your business size and goals.

See Also

Understanding The Expenses Involved With Vending Machines

Pricing Factors For Tailored Vending Machine Solutions

Detailed Analysis Of Features Influencing Vending Machine Prices

Comprehensive Review Of Vending Models, Features, And Returns

Boosting Office Efficiency Using Intelligent Vending For Small Teams