Building Workforce Resilience in Automated Warehouse Operations

Warehouses are changing fast because of automation.

In 2024, about 25% of warehouses use automation.

Ten years ago, only 5% used it.

By 2027, experts think over 60% will use automation.

This change drives workforce adaptation as workers learn new skills. They need digital literacy and process optimization. Human skills remain crucial, even with the rise of machines. The pandemic highlighted issues in supply chains, prompting companies to assist workers in adapting. They implement real-time feedback, gamification, and labor management systems. These tools help workers stay engaged and resilient.

Key Finding | Description |

|---|---|

Engagement Techniques | Real-time insights and gamification help workers do better and stay longer |

Performance Tracking | Clear reports help manage workers today |

Labor Management Systems | Fast feedback and rewards make jobs more enjoyable |

Workers become stronger through workforce adaptation by learning new skills. They leverage technology and maintain flexibility.

Key Takeaways

Automation in warehouses is increasing fast. Workers need to learn new skills to keep their jobs.

Using real-time feedback and gamification helps workers feel important. These methods also help workers stay longer at their jobs.

Learning new skills and updating old ones is very important. Companies that train workers have happier staff and fewer people quitting.

Collaborative robots, called cobots, make work safer and faster. Cobots let workers spend more time making decisions and checking quality.

Digital learning platforms give workers flexible ways to train. These tools help workers keep learning skills needed for automation.

Automation’s Impact on Warehouse Roles

Shifting Job Responsibilities

Automation has changed how people work in warehouses. Workers who once lifted boxes now watch machines and fix problems. Forklift drivers use automated systems to help them. Shipping clerks see some tasks done by artificial intelligence. Order pickers do fewer simple jobs now. They spend more time making sure things are correct. New jobs like automation technicians and robotics operators are now needed. These jobs need people to know both technical and practical skills.

Tip: Learning to use new technology can help workers get better jobs.

Change in Job Role | Description |

|---|---|

Job Quality | Order pickers do less boring work and focus on more important tasks. |

Skill Requirements | Some companies lower skill needs to train faster, but this can keep wages low. |

Management Practices | Using algorithms gives managers more control and workers less freedom. |

New Skill Demands

Automated warehouses need workers with different skills. Employees must know how to use barcode scanners and RFID systems. They should know how to use logistics software, like transportation management systems. Digital literacy is very important. Workers also need soft skills like understanding feelings, self-control, and good communication.

Barcode scanning and RFID help track items.

Logistics software helps with shipping and receiving.

Understanding feelings helps workers handle changes.

Being aware of what is happening keeps everyone safe.

Good communication helps teams work well together.

Technical Skill | Description |

|---|---|

Barcode Scanning and RFID Technology | Helps keep track of inventory accurately. |

Logistics Software | Used for managing shipments and warehouse work. |

Challenges and Opportunities

Warehouse workers face many problems. There are not enough skilled workers, even though jobs are growing by 20.5%. Rent and other costs are going up, so budgets are tight. Safety is still a big problem, and injuries mean more claims for money. Mistakes and slow work can waste up to 30% of money spent. But automation brings new jobs in technology, data analysis, and system care. Learning new skills helps workers move into these jobs and grow in their careers.

Note: Using automation can help workers find new and exciting jobs in warehouses.

Challenge | Description |

|---|---|

Lack of skilled Human Resources | Not enough trained workers for new jobs. |

Operational Complexities | Workers must meet customer needs for speed and accuracy. |

Rising Real Estate and Operating Expenses | Warehouse space and running costs are getting higher. |

Safety and Compliance Risks | More injuries and rules make work harder. |

Economic Inefficiencies | Up to 30% of money can be wasted in operations. |

Opportunities for Career Growth | New jobs in technology and data analysis help workers move up. |

Workforce Adaptation Strategies

Upskilling and Reskilling

Upskilling and reskilling help workers learn about new technology. Companies that train workers see happier employees and fewer people quitting. Warehouses have a turnover rate of about 37%. This is much higher than the average rate of 3.6%. When workers learn new things, they feel important and want to stay. Almost 70% of adults feel good about learning new skills for automation.

Key skills for today’s warehouses are:

Digital literacy: Workers use digital tools and platforms.

Data interpretation: Employees read reports and data to make smart choices.

Process optimization: Teams find better ways to do their work.

Training gives workers confidence and helps them rely on themselves. This makes warehouse teams stronger and more productive.

Many top warehouses test collaborative robots and automated vehicles. They also train workers from other departments. This helps fill open jobs fast and keeps teams flexible.

Employee Engagement

Employee engagement is very important for workforce adaptation. Engaged workers share ideas and help each other solve problems. Companies break down barriers by encouraging teamwork and open talks. They ask for feedback from workers, suppliers, and customers. This makes everyone feel included and trusted.

Best ways to engage employees are:

Building a team spirit.

Letting workers switch jobs and swap shifts.

Using flexible processes so teams can change fast.

Letting company values guide how leaders talk to staff.

When workers feel heard and included, they work harder and stay longer.

A flexible workforce uses full-time, part-time, and temporary staff. This helps companies handle busy times and surprises. Job rotation and cross-training keep workers interested and ready for new tasks.

Human-Tech Collaboration

Human-tech collaboration means people and machines work together. Automated mobile robots do simple jobs, so workers focus on picking and checking quality. This lowers physical stress and makes jobs better. Automation also helps companies grow fast when needed.

People are good at making decisions and solving hard problems. Robots do easy jobs faster and help stop mistakes. When people and machines team up, warehouses get more done, stay safer, and make fewer errors.

Some best ways for human-tech collaboration are:

Start with small tests for new technology.

Teach workers to use and fix automated systems.

Check performance data often to stay flexible during busy times.

Use automation for easy jobs, but let people make tough choices.

Case Study Title | Key Insights |

|---|---|

Automation helps companies stay productive when there are not enough workers. It also brings in skilled workers by offering modern jobs. | |

Labor Management in Automated Warehouses & The Human Factor | Mixing technology and people makes workers better and more valuable. Training in robotics and inventory management is important. |

Companies that mix technology with human skills build strong teams. This helps workers adapt and get ready for the future.

Implementing Adaptation Initiatives

Vision and Roadmap

A clear plan helps workers adjust in automated warehouses. Leaders set goals that fit the company’s needs. They look at new technology and vendors before choosing. Smart use of automation with warehouse systems makes work better. A step-by-step plan matches automation with company goals. Change management helps workers learn new tools and ways to work.

Key parts of a strong plan are:

Step-by-step plans that fit business needs

Mixing new technology with old ways

Change management to help workers

Planning for growth with modular automation saves money later. Good connections with old systems keep work running smoothly. Buying flexible automation helps companies work well for a long time.

Building Digital Skills

Warehouse workers need new digital skills to keep up. Working with robots lets machines do easy jobs. Workers can focus on harder tasks. Wearable tech like smart glasses and wrist scanners make work safer and faster. Virtual reality training lets workers practice without danger.

Digital Skill | Description |

|---|---|

Collaboration with Robotics | Machines do easy jobs, workers do harder ones. |

Use of Wearable Technologies | Smart glasses and wrist scanners help workers do better and stay safe. |

Virtual Reality for Training | Workers learn by practicing in a safe, fake world. |

Government and industry certificates show workers have good skills. These certificates help workers grow and feel good about their jobs.

Scaling Training Programs

Big warehouses need good ways to teach many workers. Performance support helps workers learn while working and boosts output. Learning on the job teaches real skills but can cause mistakes. Shadowing lets new workers watch and ask questions. Mentoring gives advice and support. Coaching helps workers get better through feedback. Classroom lessons work well for safety topics.

Method | Pros | Cons | Recommended for Situations |

|---|---|---|---|

Performance Support | Makes work faster, does not take much time | Only fills gaps, needs basic skills | When workers need help with certain problems |

Learning on the Job | Teaches skills right away | Mistakes can slow down work | Good for long-term training during work |

Shadowing | Lets new workers watch and ask questions | Takes time, may not match all workflows | Best for new workers at the start |

Mentoring | Gives advice and support | Depends on mentor and worker relationship | Good for new workers and more learning |

Coaching | Gives feedback and support | Should be chosen, can cost a lot | Best for skilled workers with clear goals |

Classroom Teaching | Group learning, focused lessons | Not liked by most warehouse workers | Good for safety and non-hands-on topics |

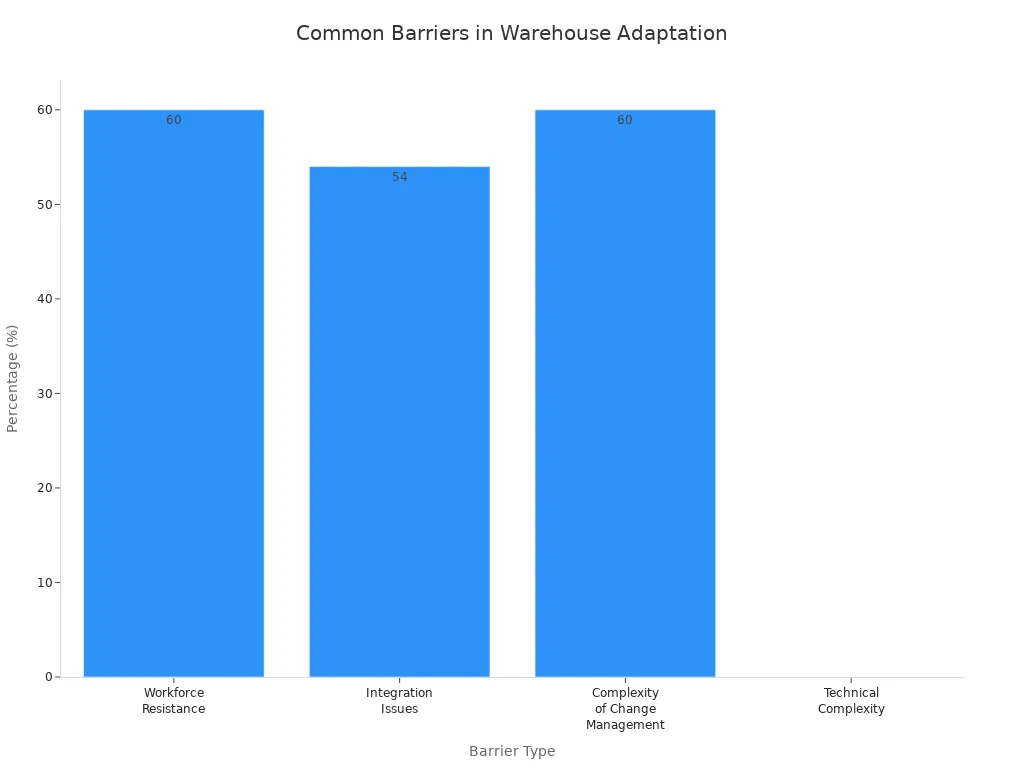

Many companies face problems like workers not wanting change, hard setups, and high costs. Change management and tech support help solve these problems.

Tech Solutions for Workforce Adaptation

Shift Management Tools

Shift management tools help teams work well together. These tools make it easy to plan who works and when. Managers use them to match workers’ choices with what the company needs. One warehouse used a scheduling tool and got more work done. They saved 17 hours each week on paperwork. Another company let workers pick their shifts. Fewer people missed work, and more stayed at their jobs. Productivity went up by 14% with flexible schedules.

Workers pick shifts that fit their lives.

Companies can react fast when things get busy.

Schedules can change quickly if needed.

Shift management tools make work more flexible. They help workers feel important and keep teams strong.

Collaborative Robots

Collaborative robots, called cobots, work with people. Cobots do heavy lifting and repeat the same jobs. People make decisions and check quality. Cobots have sensors to stop accidents. This makes warehouses safer. In 2018, there were 5.1 injuries for every 100 workers. Cobots help lower this number. Studies show that working with cobots makes people happier at work and do better.

Role | Human Workers | Collaborative Robots (Cobots) |

|---|---|---|

Task Type | Decision-making and quality control | Heavy lifting and repetitive motions |

Safety Impact | Reduced workplace injuries | Handles labor-intensive duties |

Efficiency | Focus on complex tasks | Enhances overall productivity |

Cobots and people together make warehouses safer and better. Workers can learn new skills and do harder jobs.

Digital Learning Platforms

Digital learning platforms help workers learn new things all the time. These systems give each worker training that fits them. Workers can go online, watch videos, and take quizzes. Managers can update lessons so everyone learns the latest things. One company used daily check-ins and everyone passed their tests.

Courses fit each worker’s job and skill level.

VR technology helps train for different needs.

Learning management systems help close skill gaps and support growth.

Feature | Description |

|---|---|

Customizable Modules | |

Flexibility | Employees learn online at any time. |

Resource Efficiency | Saves time and money on training. |

Digital learning platforms help teams get ready for change. They help workers keep learning and grow with new technology.

Learning new skills all the time helps warehouse teams stay strong. The industry is changing fast. Companies that train workers make more money and have happier teams. Training helps teams work better together. When companies keep helping their workers learn, they can use new technology more easily. This also helps them get ready for the future. Leaders can help by showing how to learn and grow. They should support their teams and set a good example.

Using workers well helps the best warehouses do better.

When people and machines work together, teams get stronger and do well.

Leaders need to focus on helping workers adapt as automation becomes more common.

FAQ

What skills help warehouse workers adapt to automation?

Workers need to know how to use digital tools. They must read data and find better ways to work. Teamwork and talking with others are important too. These skills help them use new technology and fix problems.

Tip: Training classes teach these skills. They help workers get ready for new jobs.

How do collaborative robots improve warehouse safety?

Cobots pick up heavy things and do the same jobs many times. Workers check if things are right and make choices. Cobots have sensors that help stop accidents.

Benefit | Description |

|---|---|

Fewer Injuries | Cobots help stop accidents |

Better Jobs | Workers do safer work |

Why is employee engagement important in automated warehouses?

Engaged workers share ideas and help each other. They feel important and want to stay. Companies use feedback and teamwork to build trust.

Workers try new jobs and learn new things.

Teams work together to fix problems.

What technology supports workforce adaptation?

Shift management tools, cobots, and digital learning platforms help workers. These tools make schedules easy to change, keep people safe, and give training.

Note: Technology helps workers learn and grow with automation.

How can leaders support workforce resilience?

Leaders set clear goals and give training. They ask for feedback and support teamwork. They help workers learn new skills and handle changes.

Action | Result |

|---|---|

Training | Teams get stronger |

Feedback | Work gets better |

See Also

Automated Vending Machines: Revolutionizing Fast Food Service

The Future Is Here: Embracing AI-Driven Retail Stores

Exploring AI-Enhanced Vending Machines for Today's Retail Needs

Boosting Office Efficiency with Intelligent Vending Machine Solutions

Transforming Online Retail Management with AI-Powered Solutions